TITANUS

SUPER·SENS

®

Pipe

Design

TSS_04_A-en-e

Data: 02/09

4 –

21

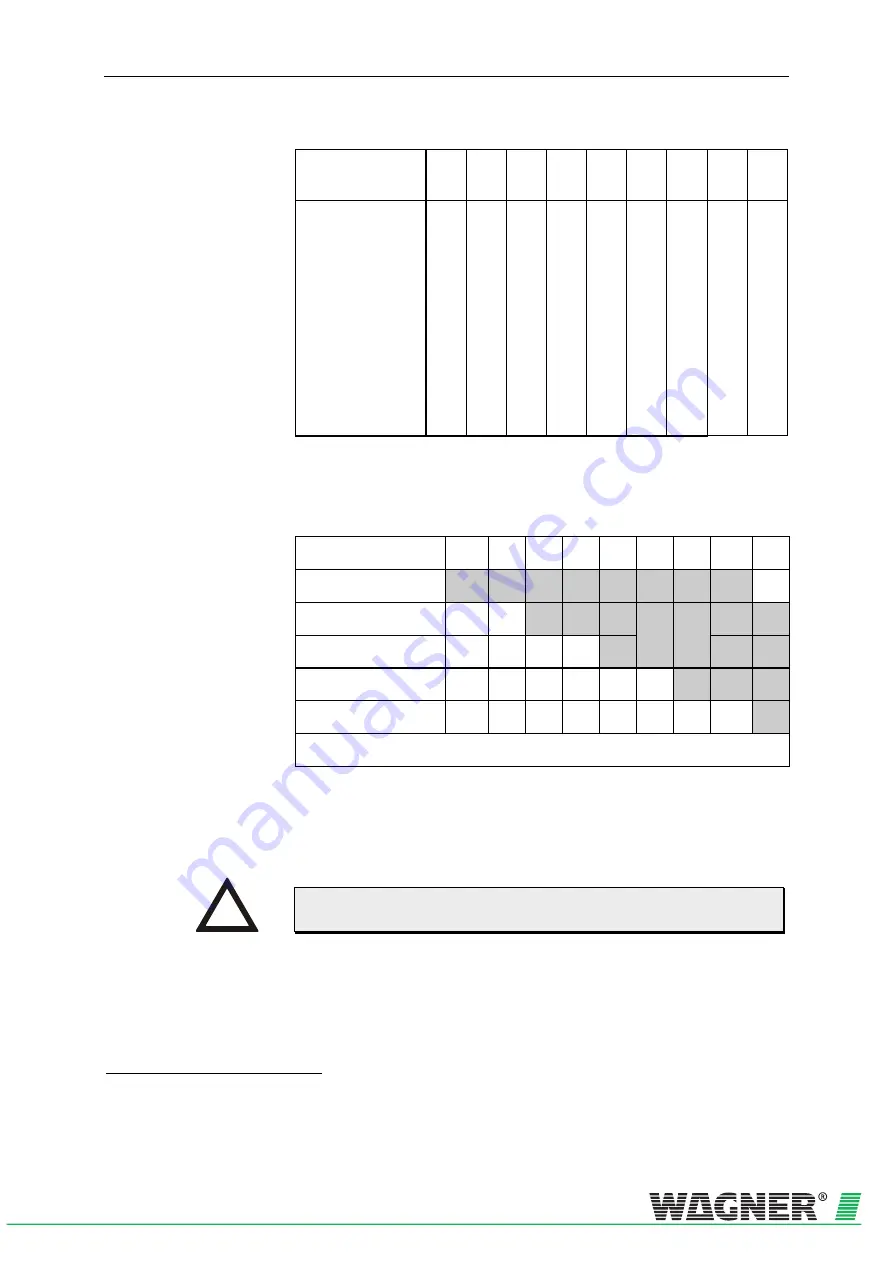

Aspiration apertures

Number of aper-

tures

2 3 4 5 6 7 8 9 10

Sampling aperture

∅

in mm

3F

4

)

A

B

C

D

E

F

G

H

I

J

6,8

6,8

—

—

—

—

—

—

—

—

5,2

5,6

5,6

—

—

—

—

—

—

—

4,4

4,6

5,0

5,2

—

—

—

—

—

—

3,8

4,0

4,2

4,4

4,6

—

—

—

—

—

3,4

3,6

3,6

3,8

4,0

4,0

—

—

—

—

3,2

3,4

3,4

3,6

3,8

4,0

4,2

—

—

—

3,0

3,0

3,2

3,2

3,4

3,6

3,8

4,0

—

—

3,0

3,0

3,2

3,2

3,4

3,6

3,8

3,8

4,0

—

3,0

3,0

3,2

3,2

3,4

3,6

3,8

3,8

4,0

4,0

I-pipe system triggering thresholds

Triggering threshold

Number of apertures

2

3

4

5

6

7

8 9

10

1

blocked aperture

III

III

III

III

II

II

I

I —

4F

5

2

blocked apertures

{

5F

6

{

III

III

III

III

II

II

I

3

blocked apertures

{

{

{

{

III

III

III

III

II

4

blocked apertures

{

{

{

{

{

{

III

III

III

5

blocked apertures

{

{

{

{

{

{

{

{

III

… has/have been detected at setting level x

Example

If blockage of 1 aspiration apertures of a total of 9 aspiration aper-

tures is intended to be detected, the air flow monitoring setting

switch should be set to level I.

Air flow monitoring level I, II or III should be set in any case for project

planning in conformity with EN 54-20.

4

Press cut diameter in aspiration-reducing film sheet

5

— not possible

6

{

not purposeful

INSTRUCTION