52

VERSION 01/2018

ORDER NUMBER DOC 2385674

TOPFINISH Bell 1S

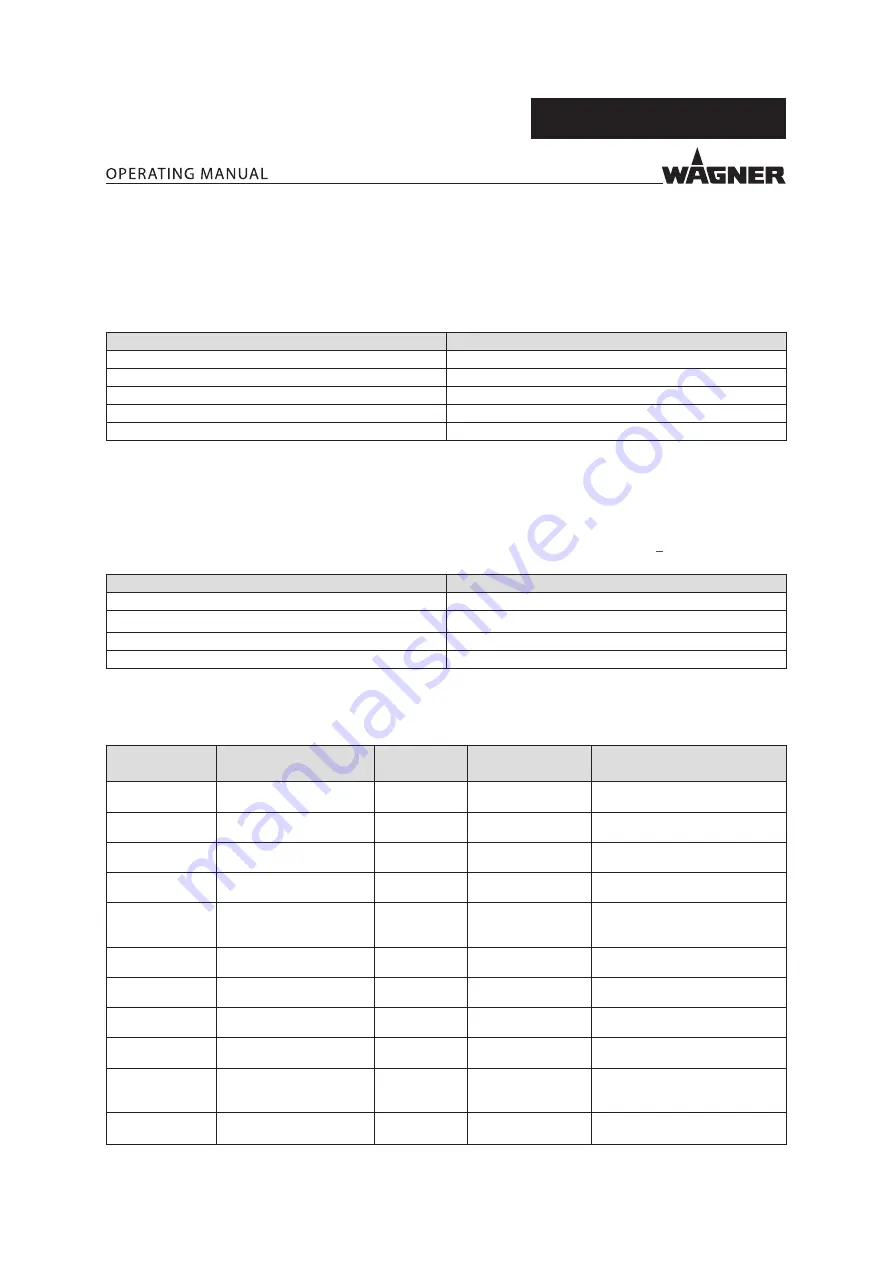

8.2.4 CHANGE INTERVALS FOR KEY COMPONENTS

The values provided below are averages, which may vary depending on lacquer type,

lacquer application rate and bell plate speed.

WAGNER recommends replacing these components as stated as a form of preventive

maintenance in order to avoid reductions in quality and unforeseeable production stops.

Component

Change interval

Consistal bell plate

5000 h

Titanium bell plate

8000 h

Distributor disc

1500 h

Air bearing

< 10000 h

Product valve

8000 h

8.2.5 MAINTENANCE PROCEDURES

The maintenance intervals should be adapted by the operator depending on the level of

use and if necessary the level of soiling.

If in doubt, we recommend contacting J. Wagner GmbH's specialist personnel.

The valid health and safety specifications and safety instructions provided in Chapter

must be adhered to for all maintenance work.

Maintenance work

Time stamp

Clean air control ring

every 4 to 8 hours

Clean bell plate

every 4 to 8 hours

Disassemble and clean air deflector ring

daily

Remove and clean bell plate

daily

For safe operation of the high-speed rotary atomizer, intervals are defined for all recurring

checks.

These checks serve to check the condition of the high-speed rotary atomizer.

The checks needed are described in the tables below.

Location

Description

Inspection

interval

Type of

inspection

Inspection criteria

Spray booth

Contamination by product

in the booth

daily

Visual inspection

No product deposits on the

components

Spray booth

Supply and exhaust air

daily

Function test

Undertake check during

operation

Spray booth

Temperature and humidity daily

Measurement

Measured values in nominal

range

Spray booth

Air settling rate

daily

Measurement

Measured values in nominal

range

High-speed rotary

atomizer

Vibrations

daily

Listening check and

visual inspection

Determine vibrations with

suitable measuring device (limit

value with fitted bell 3mm/s)

High-speed rotary

atomizer

Operating noise

daily

Listening check and

visual inspection

No operating noise present

High-speed rotary

atomizer

Damage to the housing

daily

Visual inspection

No damage

High-speed rotary

atomizer

Housing contamination

daily

Visual inspection

No abnormal contamination of

the housing

High-speed rotary

atomizer

Union nuts for half shells

daily

Visual inspection

Check whether thread has been

greased sufficiently with Vaseline

High-speed rotary

atomizer

Air control ring

daily

Visual inspection

Check whether air control ring

has been greased sufficiently with

Vaseline

High-speed rotary

atomizer

External air

daily

Listening check

No external air audible