4

VERSION 02/2019

ORDER NUMBER DOC 2397374

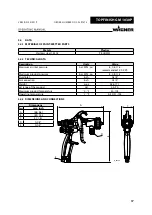

TOPFINISH GM 1030P

Training of Assembly/Commissioning Personnel

Typical Airspray Spraying System

Ventilation of the Spray Booth

Verifying a Safe Operational Condition

Training the Operating Personnel

Starting to Spray with the Airspray

Pressure Relief / Work Interruption

Cleaning the Nozzle and Eliminating Nozzle Clogging

Flushing and Cleaning the Spray Gun

Safety Checks and Maintenance Intervals

Replacing the Product Hose or Air Hose

TROUBLESHOOTING AND RECTIFICATION

Changing Shaping Air Regulator

Summary of Contents for TOPFINISH GM 1030P

Page 1: ...B_06965 TOPFINISH GM 1030P Airspray manual gun for flat and round jet nozzles Version 02 2019...

Page 2: ......

Page 26: ......

Page 51: ......