11

W 125

GB

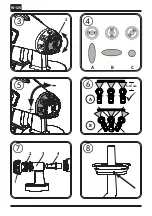

the gun body's 3 guide rails.

the gun body's 3 guide rails.

2) Put the air cap onto the nozzle and tighten it using the union nut.

3) Place the container seal from below on the suction tube and slide it over the collar,

while turning the container seal slightly.

4) Insert the suction tube with container seal in the gun body.

11. Maintenance

WARNING! Never operate the machine without the air filter; dirt could be

sucked in and interfere with the function of the machine. Disconnect plug

before changing parts.

•

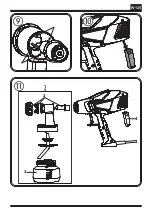

Pull the air filter out of the gun and re-insert cleaned or new air filters (Fig. 10).

12. Spare Parts List

Spare Parts List (Fig. 11)

Pos.

Designation

Order No.

1

Spray gun front part complete incl. 600 ml container

2419438

2

Set comprising union nut, air cap, nozzle

2419415

3

Container with cover

2370528

4

Air filter

2414439

13. Correction of Malfunctions

Problem

Problem

Cause

Cause

Remedy

Remedy

No coating

material

emerges from

the nozzle

•

Nozzle clogged

•

Feed tube clogged

•

Material volume too small

•

No pressure build-up in container

•

Clean

•

Clean

•

Increase the material

volume

•

Tighten container

Coating

material drips

from the nozzle

•

Nozzle worn

•

Change

Atomisation too

coarse / Spray

jet pulsates

•

Viscosity of coating material too

high

•

Material volume too large

•

Nozzle contaminated

•

Air filter heavily soiled

•

Too little pressure build-up in

container

•

Thin

•

Reduce the material volume

•

Clean

•

Change

•

Tighten container