GB

25

W 150

16. Accessories

The CLICK&PAINT SYSTEM with additional spray attachments and accessories offers

the right tool for each work.

i

We recommend against using the W 150 with the Wall Extra I-Spray

spray attachment.

Further information about the WAGNER range of products for renovating is

available under www.wagner-group.com

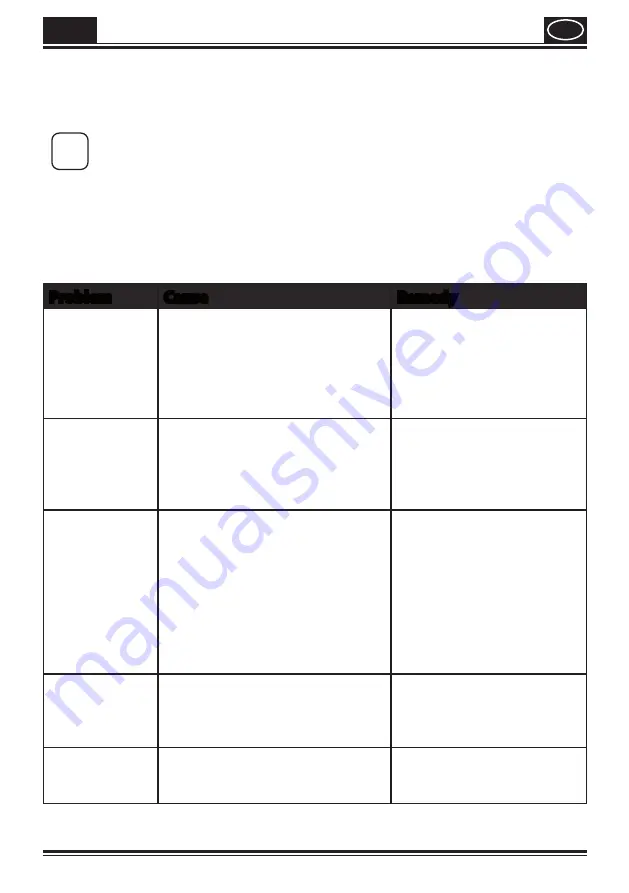

17. Correction of Malfunctions

Problem

Cause

Remedy

No coating

material

emerges from

the nozzle

•

Nozzle clogged

•

Feed tube clogged

•

Material volume setting turned

too far to the left (-)

•

Feed tube loose

•

No pressure build-up in container

➞

Clean

➞

Clean

➞

Turn to the right (+)

Insert

➞

Tighten container

Coating

material drips

from the nozzle

•

Nozzle loose

•

Nozzle worn

•

Nozzle seal is missing or worn

•

Coating material assembly at air

cap, nozzle or needle

➞

Tighten

➞

Change

➞

Insert an intact nozzle seal

➞

Clean

Atomisation too

coarse

•

Viscosity of coating material too

high

•

Material volume too large

Material volume adjusting screw

turned too far to the right (+)

•

Nozzle contaminated

•

Air filter heavily soiled

•

Too little pressure build-up in

container

➞

Thin

➞

Turn material volume

adjusting screw to the

left (-)

➞

Clean

➞

Change

➞

Tighten container

Spray jet

pulsates

•

Coating material in container

running out

•

Air filter heavily soiled

•

Nozzle seal is missing or worn

➞

Refill

➞

Change

➞

Insert an intact nozzle seal

Coating

material causes

"paint tears"

•

Too much coating material

applied.

➞

Turn material volume

adjusting screw to the

left (-)

Summary of Contents for W 150

Page 1: ...wagner group com D GB NL F WOOD METAL SPRAYER W 150 ORIGINAL BETRIEBSANLEITUNG...

Page 3: ...W 150 click c d 2 1 A B C...

Page 4: ...W 150 5 15 cm g A B 14 13 15 18 4 3 1 2 3 4 C...

Page 5: ...W 150 13 12 14 6 1 2 11 5 4 3 10 9 8 7 1 1 2...

Page 6: ...W 150 D 1 14 15 28 29 42 43 56 58 GB NL F Fragen Questions Des questions Vragen...