UK

5

Safety precautions

●

Before connecting the unit to the mains network, ensure that the available line voltage is identical to that

specified on the rating plate.

●

Only connect the unit to the line current while it is switched off.

●

Unplug the power plug when not in use.

●

Power cable and power plug must be undamaged. Replace damaged parts immediately.

●

Only professionals may be allowed to make repairs to the electrical system of the unit.

●

Never submerge the unit in liquid!

●

The power plug must be unplugged when the unit is connected to a faucet for cleaning!

●

Do not use hot water for rinsing out and cleaning.

●

The unit is not a toy; keep it away from children.

●

The unit may not be used in workplaces bound by the explosion-protection regulations.

●

Do not point the paint roll or accessories toward yourself; danger of injury by ejected material.

W 3400 Paint Roller

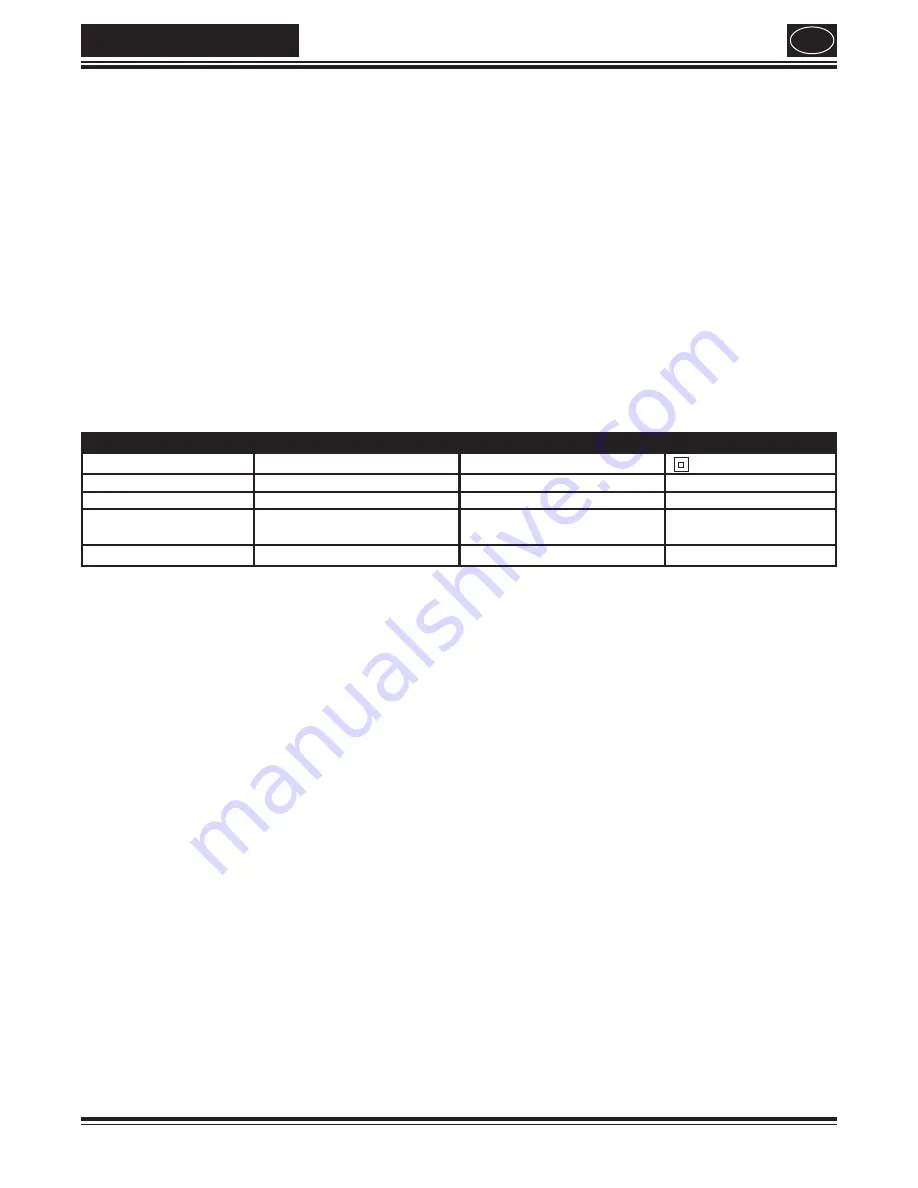

Technical data: W 3400

Voltage:

230 V/50 Hz

Double insulation:

Power consumption:

45 W

Oscillation level:

<2.5 m/s²

Max. volume:

0.45 l/min

Sound pressure level:

<70 dB(A)

Max. operating

4 bar

Operating mode:

30 min. ON

overpressure:

Weight:

1.6 kg

10 min. OFF

hhhh

Materials to be processed:

Dilutable dispersion paints and latex paints for interior and exterior walls.

Materials not to be processed:

Paints and lacquers containing solvents and materials containing heavily abrasive components.

Preparation and mounting

1.

Mounting the paint roll (figure 1):

Screw in sealing cap (A) clockwise and hold (B) firmly. Slide on mounted roll body until it engages at

(C).

2. Mount deaeration unit, close air bleed valve (figure 5, B) and connect hoses (figure 2): slide suction

hose (A), air bleed hose (B), paint feed hose (C) onto the respective connection pieces until they stop.

Slide on screw sleeves and tighten.

3. Before beginning work, cover or tape up the floor, furniture, door frames and other objects. Place the

unit on a sufficiently sized piece of plastic or cardboard.

4. Stir the paint well and thin up to 10 % if necessary (observe information from manufacturer)

5.

Submerge suction hose with suction filter (figure 3) to the bottom of the paint container and fasten to the

paint container edge with clamp.

6. Open dosage valve at handle. Switch unit on (figure 4). Suction and paint feed hoses and paint roll fill

with paint in approx. 2 min. The unit is ready for operation when the first drops of paint emerge. Set the

paint feed as required using the dosage valve. When closing the dosage unit, the pump switches off

automatically after reaching its maximum pressure.

Summary of Contents for W 3400

Page 1: ...W 3400 D GB 2 Jahre GARANTIE 2 years WARRANTY...

Page 2: ...1 2 3 4 5 6 A B C A B C A B A B...

Page 3: ...7 8 9...

Page 4: ...12 10 A B C 11...