Summary of Contents for W 600 FLEXIO 18V

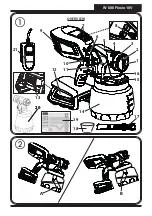

Page 2: ...W 600 Flexio 18V b A B a 11 15 16 6 9 4 5 3 1 12 14 18 17 19 7 OVERVIEW 20 8 2 10 13 21 20...

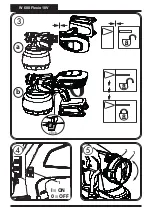

Page 3: ...W 600 Flexio 18V click c a b 1 2 1 I ON 0 OFF...

Page 4: ...W 600 Flexio 18V 2 1 A B C 1 A B 1 2...

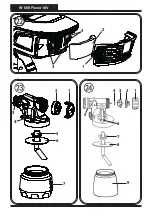

Page 5: ...W 600 Flexio 18V 5 15 cm 20 30 cm A B C 1 1 2 3 1 2 3...

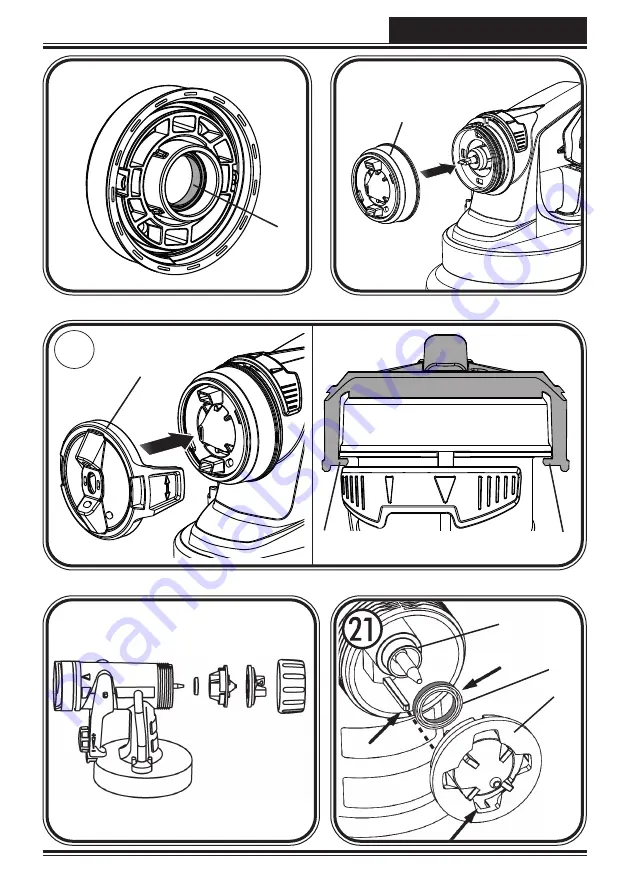

Page 6: ...W 600 Flexio 18V 4 2 1 2 2 1 2 3...

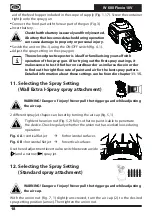

Page 7: ...W 600 Flexio 18V 1 2 3 4 5 6 7 1 2 7 8 3 4 5 6 9 1 2 3 3...