GB

12

W 95

●

The spray guns are not to be cleaned with flammable solvents which have a

flashpoint under 21°C.

●

Take precautionary measures against potential hazards from the spray liquid and

follow any instructions given on containers or laid down by the manufacturer of the

liquid.

●

Do not spray any liquid of unknown hazard potential.

●

Wear a breathing mask and ear protection.

Materials to be used:

Paints and varnishes containing solvents, acrylic enamel paints, water-soluble

varnishes, glazes, polishes, wood preservatives, disinfectants, plant protectives,

saturants, as well as oils and other watery liquids.

The following spray substances are not suitable for use:

Dispersion and latex paints, materials containing strong abrasives, glazes with coarse

particles, strippers and caustic solutions, silicate paints.

Use of these spray materials can lead to increased wear or corrosion damage in the

pump area, which are not covered by the WAGNER-Guarantee.

Preparing the Spray Material

The paints usually need to be diluted for use with the spray gun. You will find guidelines

for sprayable dilutions in the following viscosity table (viscosity = consistency of the

paint). You can achieve the correct dilution by using the viscosity test cup.

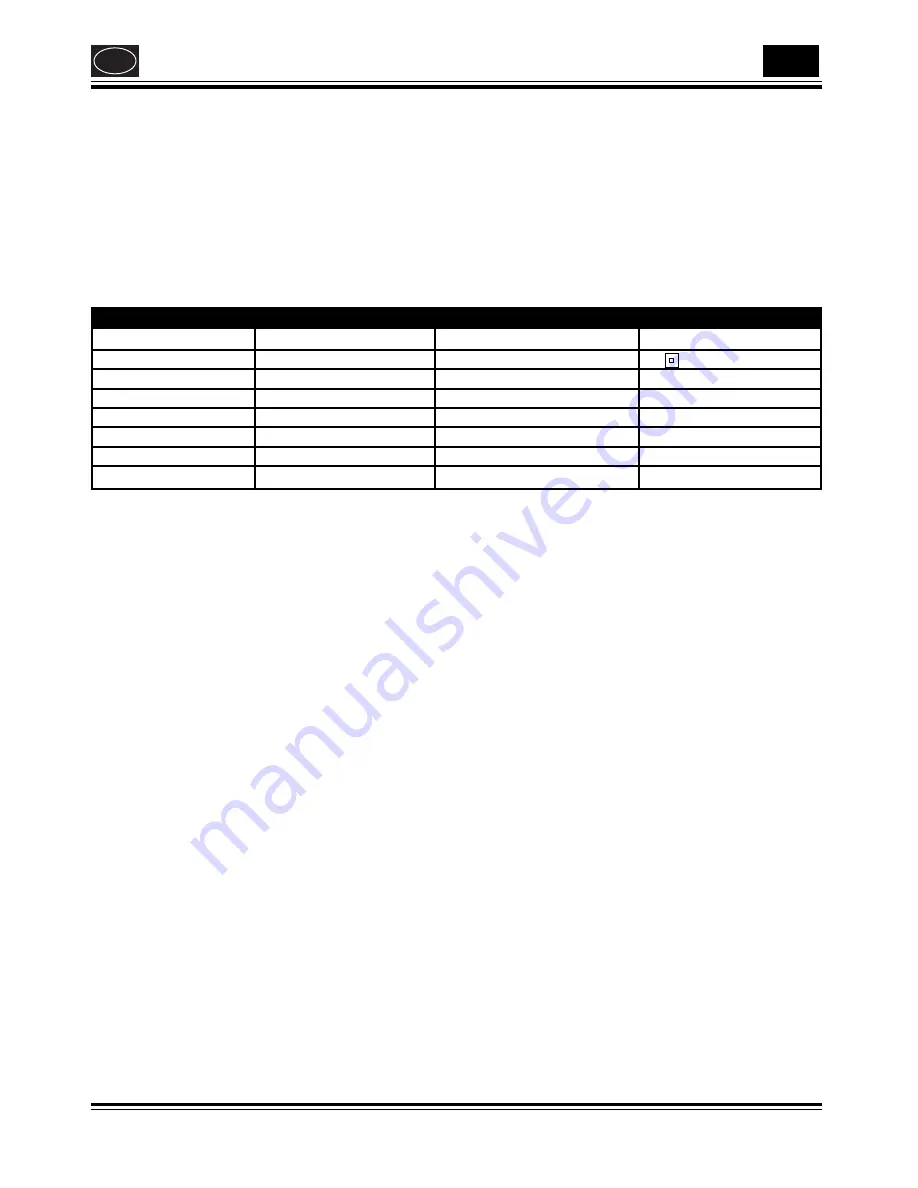

Technical Data W 95

Max. delivery ratee

140 g/min

Container capacity:

600 ml

Max. viscosity

(runout time) 60 sec.

Double insulation:

Pump:

Replaceable

Max.

pressure spikes: 120 bar

Pump cylinder:

Special steel

Power source:

230 V, 50 Hz

Piston:

Special steel Ø 5 mm

Power consumption: 70 W

Oscillation level:

10,5 m/s²

Round spray nozzle: 0,8 mm

Sound pressure level:

86 dB(A)

Weight:

1,5 kg

Sound pressure output:

99 dB(A)

Summary of Contents for W 95

Page 1: ...W 95 D GB F NL 2 JAHRE GARANTIE 2 YEARS GUARANTEE 2 ANS DE GARANTIE...

Page 2: ...1 0050342 3 4 5 0209058 2...

Page 3: ...3 6 7...

Page 4: ...8...