39

W 950 Flexio/ W 975 Flexio

G

ener

al

W

all pain

t

39

W 950 Flexio/ W 975 Flexio

EN

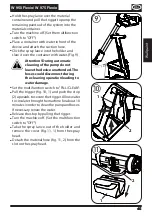

8. Preparation of the Coating Material

Mix the material well in the original container. When using interior wall paint, an agitator

is recommended.

i

W 950 / W975 has been developed for use with all conventional paints in their

undiluted form. If the surface is smooth and the paint you are using is very thick

and gel-like, dilute it by 10%. Dilution can be necessary if the atomisation is

coarse or if the flow rate is too low even at the maximum setting.

Detailed information about the various materials and the maximum permitted

dilution can be found on the manufacturers' technical data sheets (e.g. available

on the Internet).

i

Spray material that is at least at room temperature provides a better spray

result.

i

The following chapters 9-19 discuss using the W 950 / W975 as a wall paint

spraying system.

Read chapters 20-26 if you want to use varnish paints and glazes with the

W 950 / W975.

9. Preparation of the workplace (for interior wall paint)

Sockets and plugs must be masked. Risk of an electric shock as a

consequence of sprayed material entering the socket!

Mask all the areas and objects that are not to be spray painted, or

remove them from the work area. No liability is assumed for damage

due to overspray.

Silicate paint corrodes glass and ceramic surfaces

upon contact! All such surfaces must therefore be completely covered.

i

Pay attention to the quality of the adhesive tape used.

Do not use excessively strong adhesive tape on wallpaper and painted

surfaces, in order to avoid damaging these surfaces when removing the

tape. Remove adhesive tape slowly and evenly; do not use jerky movements.

Do not leave adhesive tape on surfaces any longer than necessary, in order

to minimise the possibility of residues when removing.

Also observe the adhesive tape manufacturer's instructions.