52

W 950 Flexio/ W 975 Flexio

Var

nish pain

ts and glaz

es

52

W 950 Flexio/ W 975 Flexio

EN

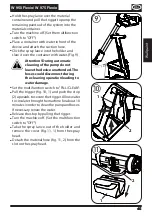

22. Setting the flow rate for the spray attachment (fig. 22).

Set the material volume by turning the regulator

on the trigger of the spray gun.

lower material volume

turn anti-clockwise

(-)

higher material volume

turn clockwise (+)

23. Spraying technique when using the spray attachment

i

The spray result depends heavily on the smoothness and cleanliness of the

surface to be sprayed. Therefore the surface should be carefully prepared and

kept free of dust.

•

Cover all surfaces not to be sprayed.

•

Cover screw threads or similar parts of the target object.

i

Important: Start at the edge of the area to be sprayed. Start the spray

movement first of all, and then press the trigger. Avoid interruptions

within the area to be sprayed.

•

The spray movement should come from the

arm, not just from the wrist. This ensures that

a uniform distance is maintained between the

spray gun and the spray surface during the

spray operation. Select a distance of 5 - 15 cm,

depending on the desired spray jet width.

Fig. 23 A:

CORRECT:

Even distance to

the object.

Fig. 23 B:

INCORRECT:

An uneven

distance will result in uneven

paint application.

•

Move the spray gun evenly cross-wise or up-and-

down, depending on the spray pattern setting.

•

An even movement of the spray gun results in an

even surface quality.

A

B