GB

17

W 450 SE

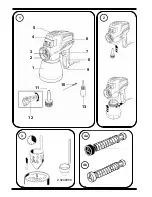

Delivery rate adjustment by 4-step electronic system (Illus.

+

)

Tapping the electronic pushbuttons reduces the stroke rate by one step at a time, from

max. delivery (100 %) in 4 steps to 12 %.

With the switch on minimum (12 %), repeated tapping will reset the 100 % stroke rate.

The electronic pushbutton can be used whether the unit is running or not.

Delivery rate

Fine adjustment knob maximum: electronic pushbutton 100 % = max. 350 g/min

Fine adjustment knob minimum: electronic pushbutton 12% = min. 25 g/min

NOTE:

Depending on the material and dilution the sprach pattern can be controlled by

the fine adjustment knob (in addition to electronic adjustment). For optimum

setting a test spraying operation is advisable. For details refer to handling table

page 15.

Spray Technique

●

The spray result depends heavily on the smoothness and cleanliness of the surface

to be sprayed. Therefore the surface should be carefully prepared and kept free of

dust.

●

Test the spray gun on cardboard or a similar surface to find the correct setting.

●

Do not spray the vessel empty. The suction tube should always be immersed in li-

quid. If air is sucked in, larger drops may result.

●

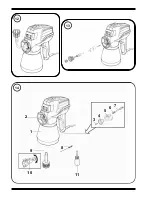

When spraying, hold the spray gun in a horizontal position. Use the

flexible nozzle

extension

(

Illus.

+

/

special accessories) for spraying upwards (e.g. a ceiling)

or downwards (e.g. an unhinged door laid on the floor).

●

Begin spraying outside of the spray area and avoid interruptions inside the spray

area.

●

Do not apply too much paint during one spraying operation. First apply a thin layer

and allow to dry briefly before applying a covering layer. This is especially important

with vertical surfaces to avoid paint sags.

●

The distance from the nozzle to the object to be sprayed depends on the delivery

rate. With a low delivery rate it is possible to go very close to the object. This

reduces the amount of spray mist.

●

The spray gun should be worked as evenly as possible during the spray operation.

Accelerating or slowing down during the spray operation causes an uneven spray

pattern, spattering, dripping and orange peel.

●

The spray movement should come from the arm, not just from the wrist. This

ensures that a uniform distance is maintained between the spray gun and the spray

surface during the spray operation

(Illus.

)

.

●

To achieve optimal spray results, spray back and forth over the surface

(Illus.

)

.