GB

19

W 450 SE

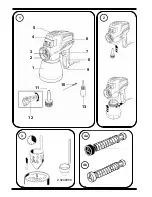

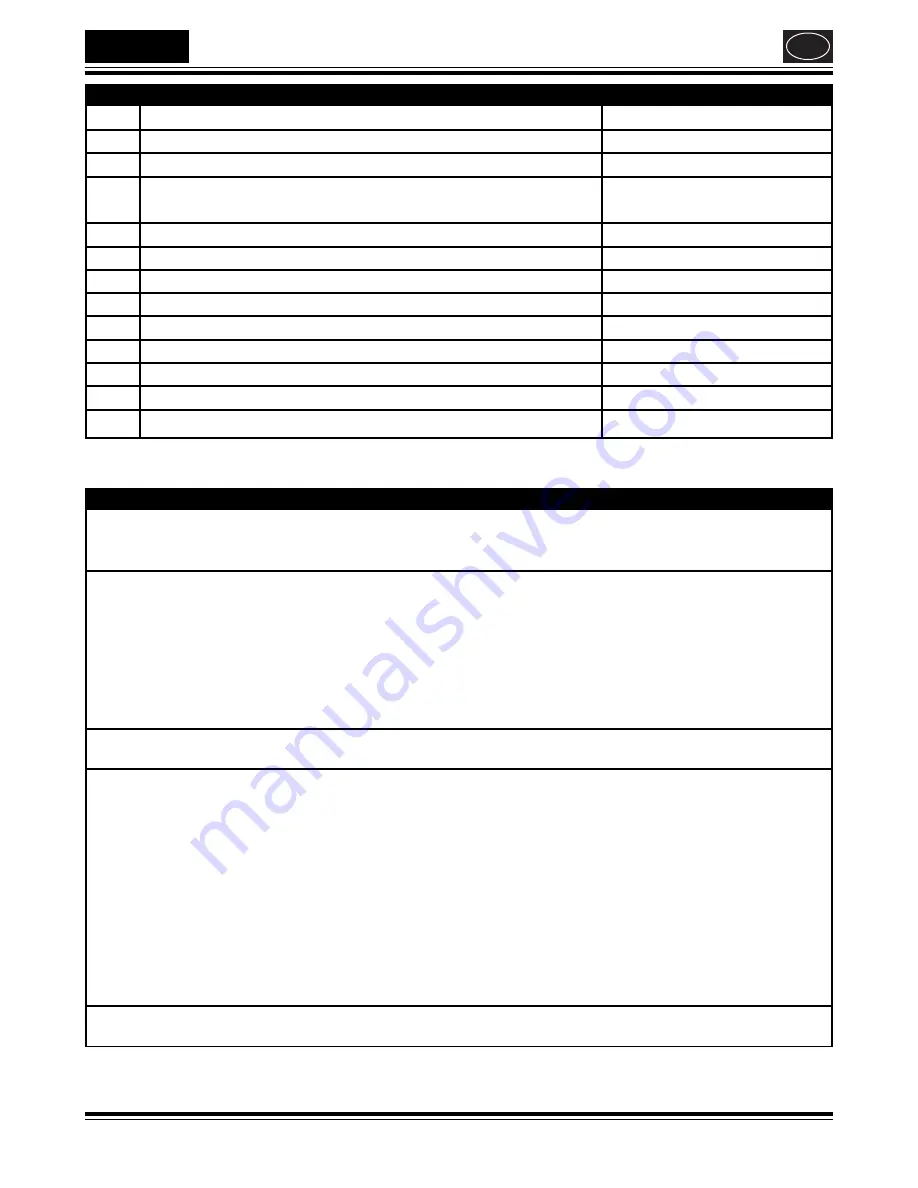

Spare Parts List W 450 SE

Pos

Name

Order No.

1

Paint container with cover

0413 909

2

Nozzle 0,8 mm

0046 903

3

Spare valve for lacquers paints

0209 041

for emulsions paints

0209 042

4

Locking nut

0413 310

5

Pump housing

0500 253

6

Piston spring

0016 101

7

Piston

0199 207

8

Cleaning brush

0514 209

9

Suction tube with filter

0046 560

10

Nozzle spanner

0199 327

11

Oil bottle

0500 320

12

Viscosity measuring cup (Illus.

)

0209 058

Malfunction

Cause

Correction

Spray gun buzzes and does

Piston stuck

Disassemble pump and

not work

clean with thinner

Defective drive

Contact point of sale

Spray gun does not suck in

No valve in the pump

Insert valve

Suction tube loose in the conical

bore

Adjust suction tube

Venting hole in pump housing

clogged

Clean

Intake hole (fitting) in pump

housing logged

Clean

Viscosity of spray material too high

Thin accordingly

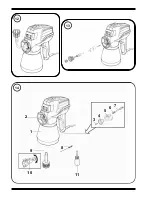

Spray gun sucks in but does

Nozzle clogged

Clean

not spray

Ducts and holes in atomiser clogged Clean

Spray gun works but sprays

Spray material in container running

unevenly

out Refill

Spray gun held inclined leading to

Use flexible nozzle

sucking in of air

extension (see accessories)

Viscosity of spray material too high

(too thick)

Dilute accordingly

Fine adjustment button not set

Reset according to spray

correctly

material

Wrong nozzle size

Change nozzle

Nozzle worn out

Replace

Valve worn out

Replace

Wrong valve inserted

Use correct valve

Step electronic system

Fault in electronic

Contact point of sale

malfunction