GB

12

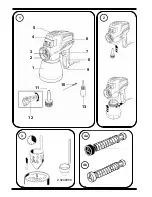

W 450 SE

e)

If you work outdoors, use only extension leads that are approved for

outdoor use.

The use of an extension lead that is suitable for outdoors reduces

the risk of an electric shock.

3. Safety of Persons

a)

Be attentive. Pay attention to what you are doing and work sensibly with a

power tool. Do not use the tool if you are tired or under the influence of

drugs, alcohol or medication.

Just a moment of inattentiveness while using

the tool can lead to serious injuries.

b)

Wear personal safety equipment and always wear safety goggles

Wearing

personal protective equipment, such as dust mask, non-slip safety shoes,

safety helm or ear protection, depending on the type of power tools, reduces

the risk of injury.

c)

Avoid accidental starting-up. Ensure that the switch is in the "OFF"

position before inserting the plug into the socket.

Accidents can occur if

you carry the power tool while your finger is on the switch or if you connect the

power tool to the power supply which it is on.

d)

Remove setting tools or wrenches before switching on the power tool.

A

tool or wrench that is in a rotating tool part can lead to injuries.

e)

Do not overestimate your abilities. Ensure that you are standing securely

and have your balance at all times.

This ensures that you can control the tool

better in unexpected situations.

f)

Wear suitable clothing. Do not wear wide clothing or jewelry. Keep your

hair, clothes and gloves away from moving parts.

Loose clothing, jewelry or

long hair can be caught in moving parts.

g)

If dust extraction or collection devices can be mounted, ensure that these

are connected and are being used properly.

Using these devices reduces

the danger caused by dust.

4. Careful Handling and Use of Power Tools

a)

Do not overload the tool. Use the power tool designed for the work that

you are doing.

You work better and safer in the specified performance range if

you use the suitable power tool.

b)

Do not use power tools whose switch is defective.

A power tool that cannot

be switched on or off is dangerous and has to be repaired.