GB

14

W 450 SE

Safety Instructions for Spray Guns

●

Caution!

Wear breathing equipment: Paint mist and solvent vapors are damaging to health.

Always wear breathing equipment and only work in well ventilated rooms or using

supplementary ventilating equipment. It is advisable to wear working clothing and gloves.

●

Wear a breathing mask and ear protection.

●

Spray materials emerge from nozzle tips under high pressure.

Attention!

Danger of injection - Never point the spray stream towards human

beings or animals. In the event of injury to the skin by paint or solvents, quick

expert treatment by a physician is essential. The physician should be informed of

the type of paint or solvent involved.

●

The spray gun is to be used only for paints and solvents with a 21° C (32° in UK)

flashpoint or higher (See information on the material tin. Hazard class A II and A III

permitted).

●

The device may not be used in workplaces covered by the explosion-protection

regulations.

●

To avoid the hazard of explosion when spraying, provide for effective natural or

artificial ventilation.

●

There must be no sources of ignition such as, for example, open fires, smoke of lit

cigarettes, cigars and tobacco pipes, sparks, glowing wires, hot surfaces, etc. in the

vicinity during spraying.

●

The spray gun is not a toy; children must therefore not be allowed to handle it or

play with it.

●

Before working on the spray gun remove the power plug from the socket.

●

Do not use the spray guns to spray flammable substances.

●

The spray guns are not to be cleaned with flammable solvents which have a

flashpoint under 21°C.

●

Caution against dangers that can arise from the sprayed substance and observe

the text and information on the containers or the specifications given by the

substance manufacturer.

●

Do not spray any liquid of unknown hazard potential.

Technical Data W 450 SE

Max. delivery rate:

20 - 350 g/min

Container capacity:

800 ml

Max. viscosity:

(runout time) 280 sec.

Double insulation:

Pump:

Replaceable

Max. pressure spikes:

180 bar

Pump cylinder:

hard metal

Power source:

230 V~

Piston:

hard metal

Power consumption:

110 W

Oscillation level:

10,5 m/s²

Round spray nozzle:

0,8 mm

Sound pressure level:

86 dB(A)

Weight:

1,5 kg

Sound pressure output:

99 dB(A)

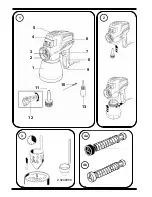

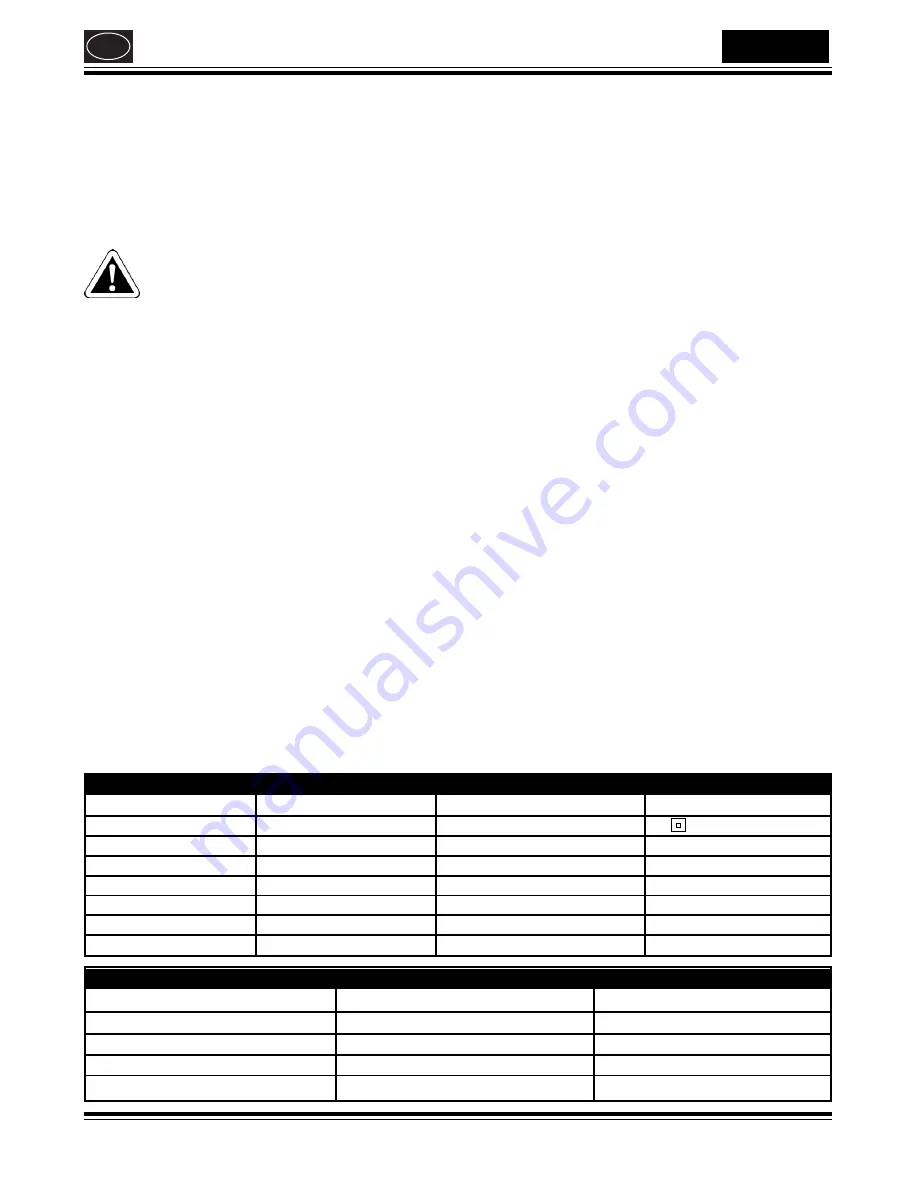

Description W 450 SE (Bild

)

1

Paint container 800 ml

6

Fine-adjustment knob

11

Suction tube

2

Locking nut

7

ON/OFF switch

12

Nozzle spanner

3

Nozzle 0,8 mm

8

Grip

13

Oil bottle

4

Housing

9

Pump housing

5

4-step electronic system

10

Cleaning brush