GB

15

W 450 SE

Materials to be used:

Paints and varnishes containing solvents, acrylic enamel paints, water-soluble

varnishes, glazes, polishes, wood preservatives, disinfectants, plant protectives,

saturants, as well as oils and other watery liquids.

Dispersion and latex paints, bituminous paints. In the case of dispersion paints that

contain fine quartz or similar materials: Observe the specifications in the handling table.

The following spray substances are not suitable for use:

Materials containing strong abrasives, glazes with coarse particles, strippers and

caustic solutions, silicate paints.

Use of these spray materials can lead to increased wear or corrosion damage in the

pump area, which are not covered by the WAGNER-Guarantee.

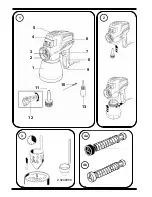

Functional Description of the Spray Gun

The spray gun sucks in spray materials. The airless atomisation results when the spray

material is pumped at high pressure through the swirl system and the nozzle bore.

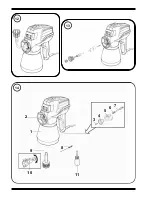

Preparing the Spray Material

The paints usually need to be diluted for use with the spray gun. You will find guidelines

for sprayable dilutions in the following handling table for viscosity (viscosity = consis-

tency of the paint). You can achieve the correct dilution by using the viscosity test cup.

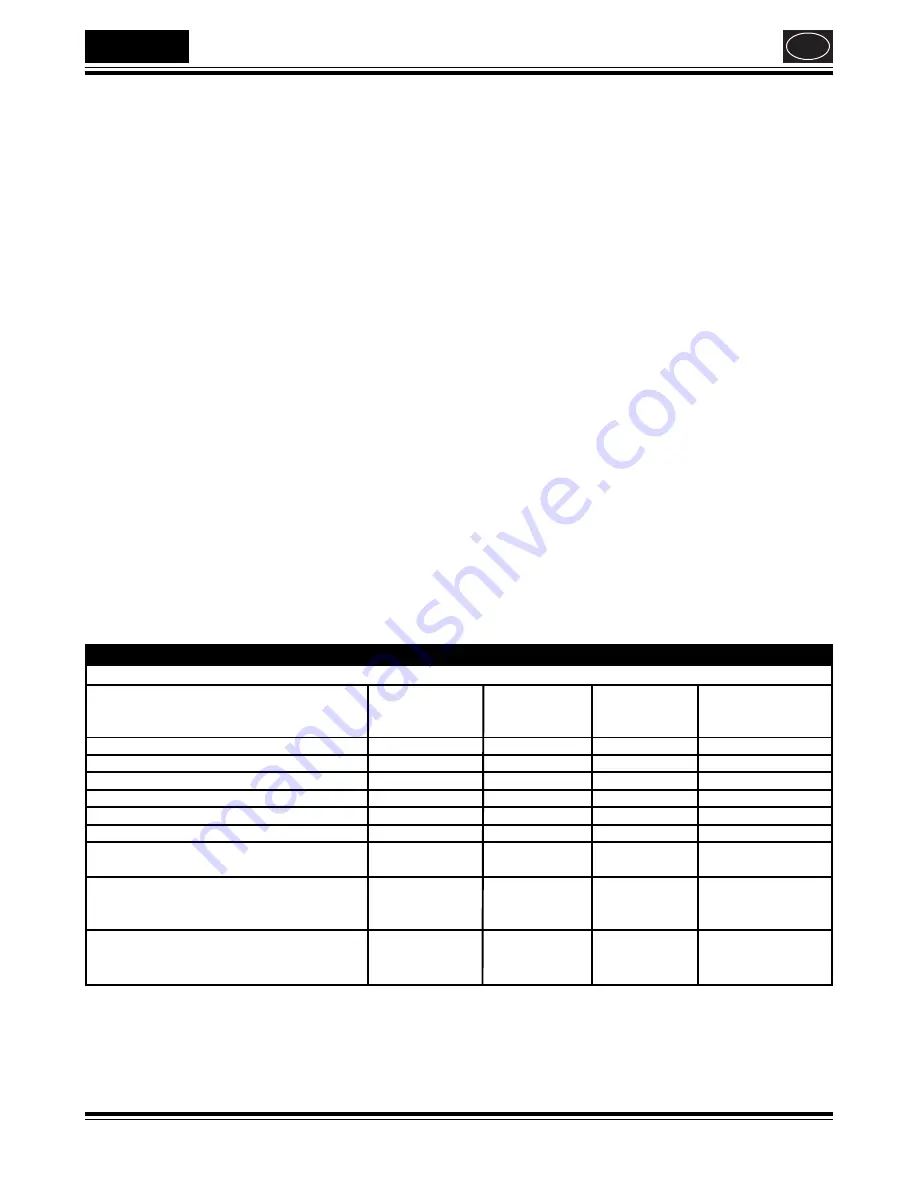

Viscosity, valve, round nozzle and multi-step electronic system

setting data Multi-step electronic system

* Standard nozzle ** Part No. see accessory list page 18.

*** With paints, which contain fine quartz or other similar components, there is increased wear of

the valve and the nozzle. According to the scope of work, always have spare parts available.

Handling table

Fine-adjustment knob

: For variable adjustment

Valve: Step electronic

Viskosity

Atomizer Roundnozzle system

Material

DIN-s

colour mm Adjustment %

Resin primers

20 - 30

black 0,8* 50/25/12

Resin lacquers 20 - 30

black 0,8 50/25/12

acrylic lacquers

20 - undiluted black 0,8 50/25/12

Radiator paints, Hammer finish paints 25 - 35 black 0,8 50/25/12

Timber impregnating undiluted black 0,8/1,2** 100

Aluminium paints

20 - 30 black 0,8 50/25/12

Underbody protection

max.

(wax and bitumen base) 80 - 100 black 1,2** 100

Plastic emulsions*** not measurable

approx. 10 - 20% white 0,8 100

dilution

1,0**

Latex paints ***

not measurable

approx. 5 - 20% white 0,8 100

dilution 1,0** 50/25/12