GB

16

WallPerfect W 665

acidic coating substances. Materials with a flash point below 21°C.

The following materials can only be processed with optional accessories:

Water- and solvent-based paints, finishes, primers, 2-component paints, clear finishes,

automotive finishes, staining sealers and wood sealer-preservatives.

Preparation of the workplace

Cover all surfaces and objects that should not be sprayed, or remove

them from the work area.

Silicate paint corrodes glass and ceramic surfaces upon contact! All

such surfaces must therefore be completely covered.

Preparation of the Coating Material

i

Spray material that is at least at room temperature (e.g. diluted with warm

water) provides a better spray result.

Attention! Do not heat spray material above 40°C.

Interior wall paints can be sprayed undiluted or slightly diluted with the spray attachment

provided. Detailed information is available in the technical data sheet of the manufacturer

(

Internet Download).

Stir the material thoroughly and dilute it in the container as per the recommended

1.

dilution

(an agitator is recommended for stirring).

Thinning recommendation

Sprayed material

Interior wall paint (dispersions and latex paint)

dilute by 10 %

If the feed rate is too low even at maximum flow setting, dilute in steps of 5 - 10 % until

2.

the feed rate meets your requirements.

Startup

Before connecting to the mains supply, be sure that the supply voltage is identical with

the value given on the rating plate.

Attach the carrying strap to the unit.

•

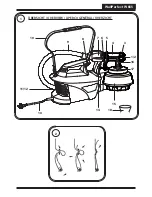

(Fig. 2)

Unscrew the container from the spray gun.

•

Aligning suction tube.

•

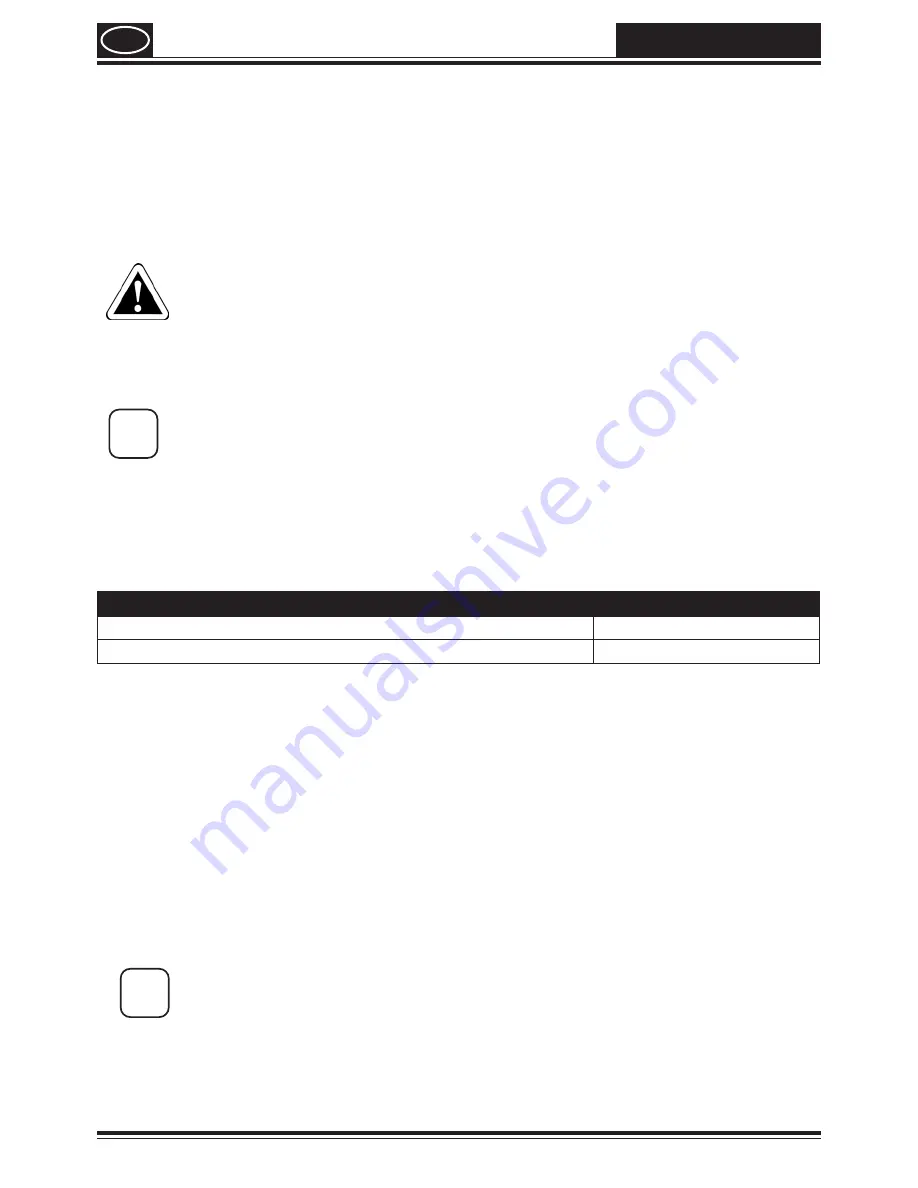

(Fig. 3)

If the suction tube is positioned correctly, the container contents can be sprayed

without almost any residue.

When spraying horizontal surfaces, turn suction tube forward. (Fig. 3 A)

When spraying objects overhead, turn suction tube back. (Fig. 3 B)

i

We recommend orienting the feed tube to the rear, to ensure optimal

coating of walls and ceilings.

Place the container on a paper base and pour in the prepared coating substance with

•

the aid of the feed hopper included in the scope of supply (Fig. 1, 18).

Screw the container tightly onto the spray gun.