GB

19

WallPerfect W 665

Assemble the parts again (see “Assembly”).

14)

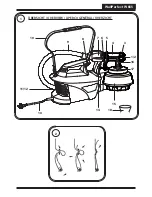

Assembly

The unit may only be operated with an integer diaphragm (Fig. 12 A, 16). Place the

diaphragm with the pin facing upwards on the bottom section of the valve. Also see

the marking on the gun body. Place on the valve cover and screw it closed. Place the

ventilating hose on the valve cover and on the nipple at the gun body.

Slide the nozzle seal (Item 4) with the groove (slot) facing forwards into the nozzle (Fig. 12 B).

Put the nozzle onto the gun body and find the correct position by turning it. Put the air

cap onto the nozzle and tighten it using the union nut.

Place the container seal from below on the suction tube and slide it over the collar, while

turning the container seal slightly. Insert the suction tube with container seal in the gun

body.

Maintenance

Change the air filter if it is soiled. Use a screwdriver to lever the cover fastening from the

unit (Fig. 11, arrow). The smooth side of the air filter (Fig. 11, 1) must be placed towards

the machine. Replace the cover on the unit until it latches.

WARNING! Never operate the machine without the air filter; dirt could be sucked in

and interfere with the function of the machine.

In order to mount the gun more easily apply lubricating grease (enclosed) liberally

to the Oring at the gun front part (Fig. 12, 18).

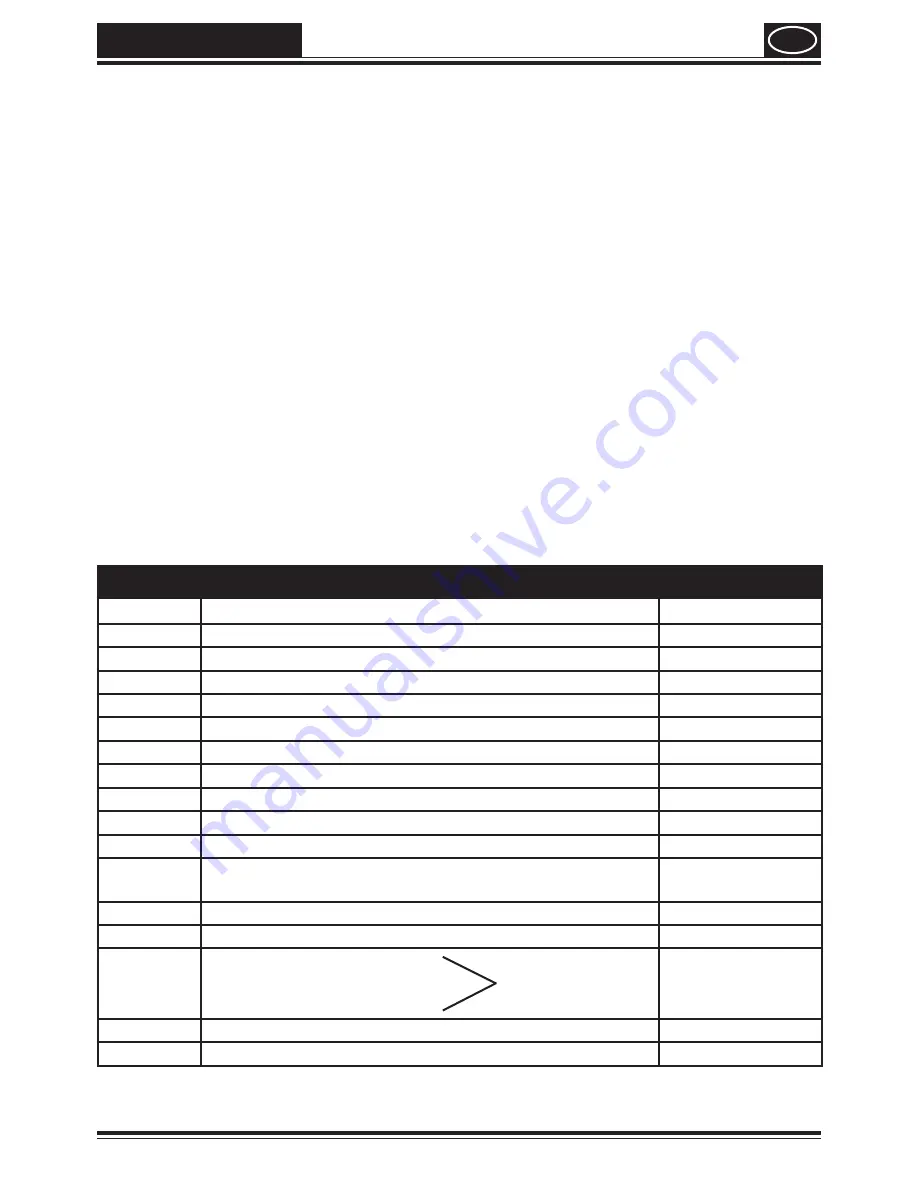

Spare Parts List (Fig. 12)

Pos.

Name

Order No.

1

Union nut

0417 471

2

Air cap

0417 470

3

Nozzle

0417 468

4

Nozzle seal

0417 465

5

WallPerfect spray attachment incl. 1800 ml. conainer

2301 734

6

Handle

2303 300

7

Air hose

2303 410

8

Carrying belt

0414 204

9

Cover

0414 302

10

Air filter

0414 700

11

Container with cover 1800 ml (only for WallPerfect

spray attachment)

2304 025

12

Suction tube

0417 473

13

Container seal

0417 474

14

Ventilating hose

15

Valve cover

2304 027

16

Diaphragm

17

Feed hopper (3x)

2304 028

Lubricating grease

9892 550