13

English

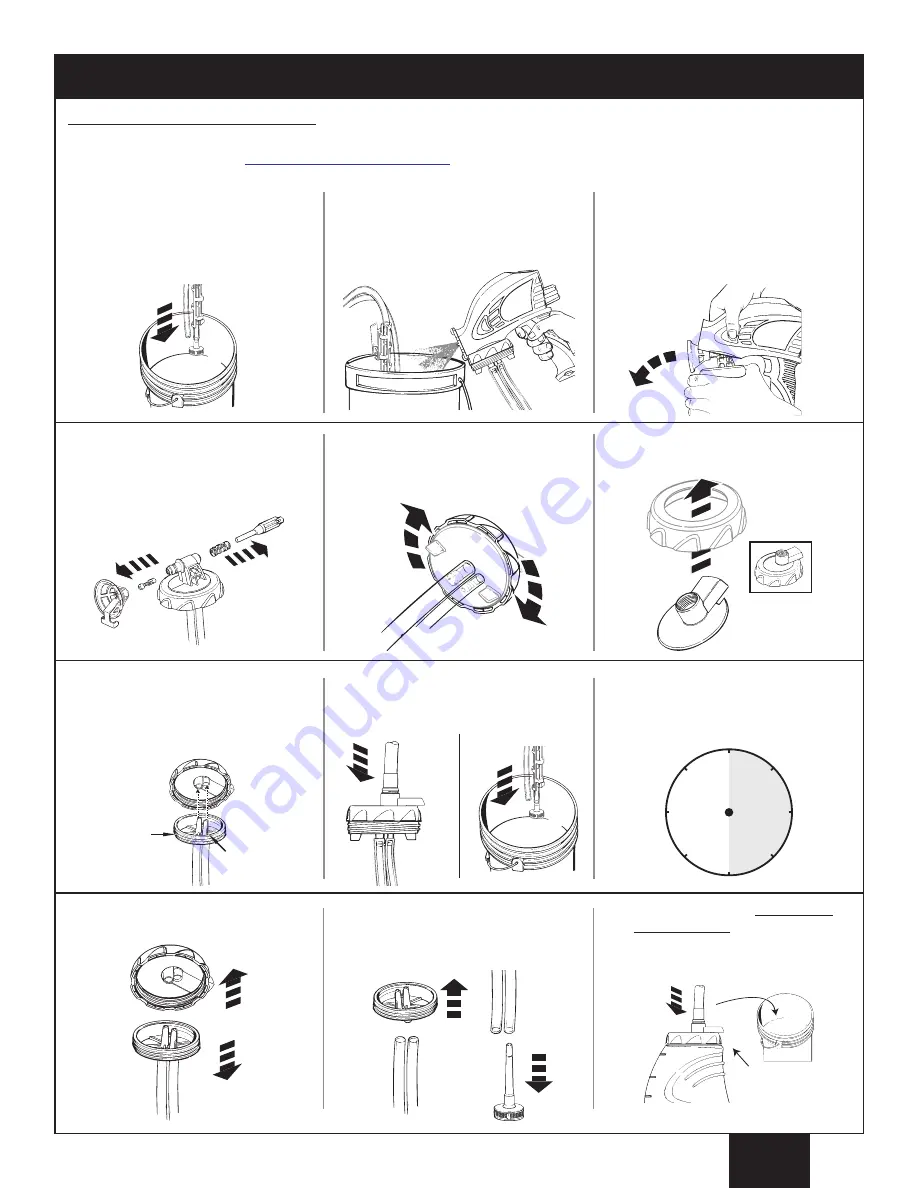

Using the Quick-clean feature (latex materials only)

Cleaning the Suction Extension

You will need a garden hose to complete the steps below. If you do not have a garden hose available, or if you used oil-

based materials, follow the

Cleanup for Oil-Based Materials

instructions on pages 14-15.

1. To purge any remaining material

left in the suction hose, remove the

suction set from the material

container and place into a waste

container.

3. Unplug the sprayer. Press the

Lock-N-Go™ buttons on both sides

of the sprayer with one hand, grab

the pump with your other hand, and

slide the spray cartridge out.

2. Point sprayer into the side of the

waste container. Trigger the

sprayer until nothing more comes

from the spray tip.

4. Remove piston, spring, spray tip

and swirl valve from the pump

housing assembly. Place all

removed parts into the fluid

container.

6. Fit the quick-clean cap into place on

the pump housing ring as shown.

5. Unlock dual hose fitting (with hoses

still attached) from pump assembly

ring.

7. Push the dual hose fitting

(a)

into

the intake and return openings on

the bottom of the quick-clean cap.

The fitting with the ridge

(b)

goes

into the return opening.

(a)

(b)

9.

SLOWLY

turn on the garden hose.

Let the water run for approximately

30 seconds. Turn the water off.

0

30

15

45

8. Thread a garden hose into the quick-

clean cap. Place hoses (with suction

set attached) into an empty bucket.

10. Remove the dual hose fitting from the

quick-clean cap.

12. Perform steps 4-8 in

Cleaning the

Fluid Container

(previous page) in

order to clean the components of

your sprayer.

(a)

11. Remove the suction set and dual

hose fitting from the suction hoses.

Place suction set into the fluid

container.