Operating manual Piston pump IceBreaker 40-200 ccm (Finishing)

7 Operation

Order number 2333538 | Edition 03/2021

49

6

7

4

1

3

B_05292

5

2

A

B

A

closed

B

open

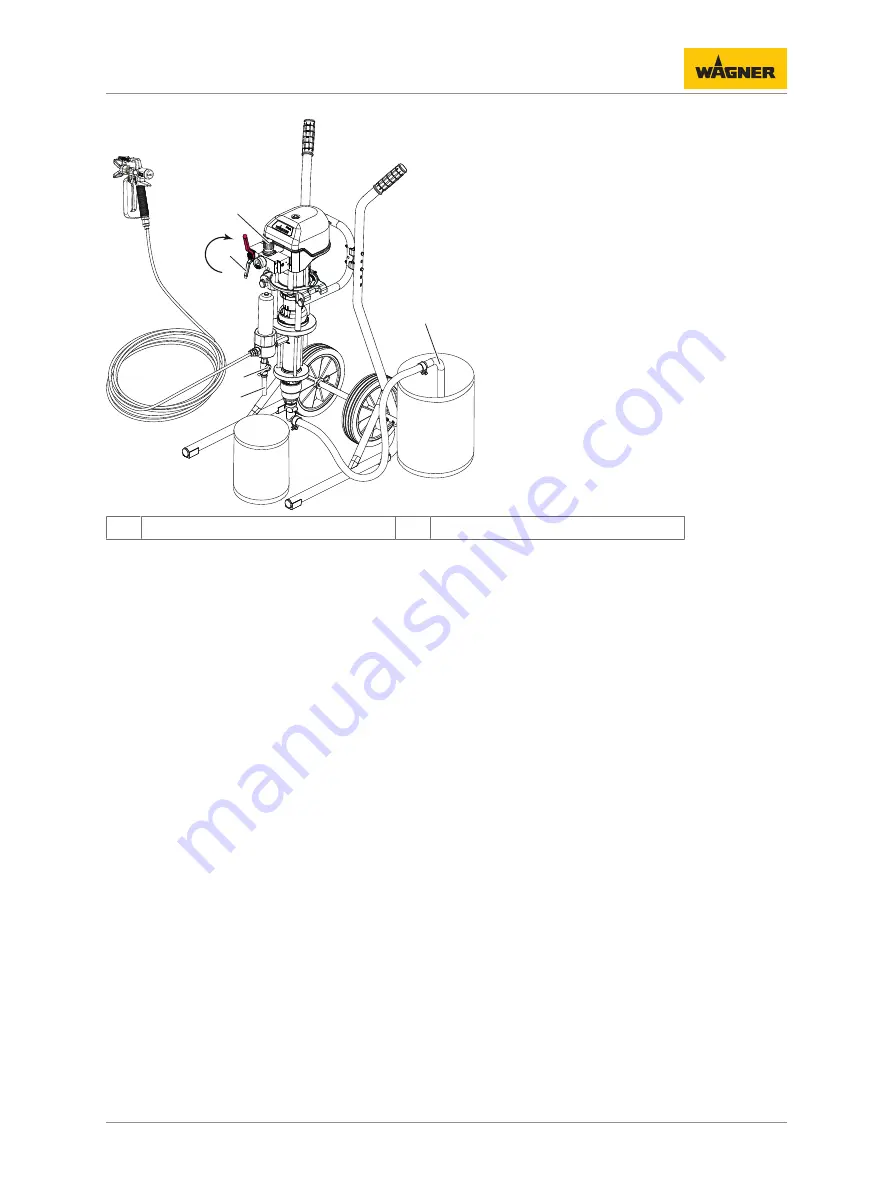

7.4 PRESSURE RELIEF / WORK INTERRUPTION

The pressure must always be relieved:

– after the spraying tasks are finished,

– before servicing or repairing the system,

– before carrying out cleaning tasks on the system,

– before moving the system to another location,

– before something needs to be checked on the system,

– before the nozzle or the filter is removed from the spray gun.

The components for pressure relief on a CE-compliant spraying system include:

– Air cock with pressure relief valve mounted between the compressed air source and the

pneumatic pump.

– Outlet equipment (return valve) mounted between pump and spray gun.

Process for relieving pressure

1. Close the spray gun.

2. Close ball valve (2).

3. Release the system of pressure by opening the spray gun.

ð

Attention: If a blocked nozzle is preventing relief, first carry out the additional steps

4 and 5, then clean the nozzle.

4. Close and secure the spray gun.

5. Open and close the return valve (3) slowly to completely depressurize the system.