2787-2147 (/0000-00x0)

Notes on Operation

Product manual | Version: 1.2.2

67

Power Supply Pro 2

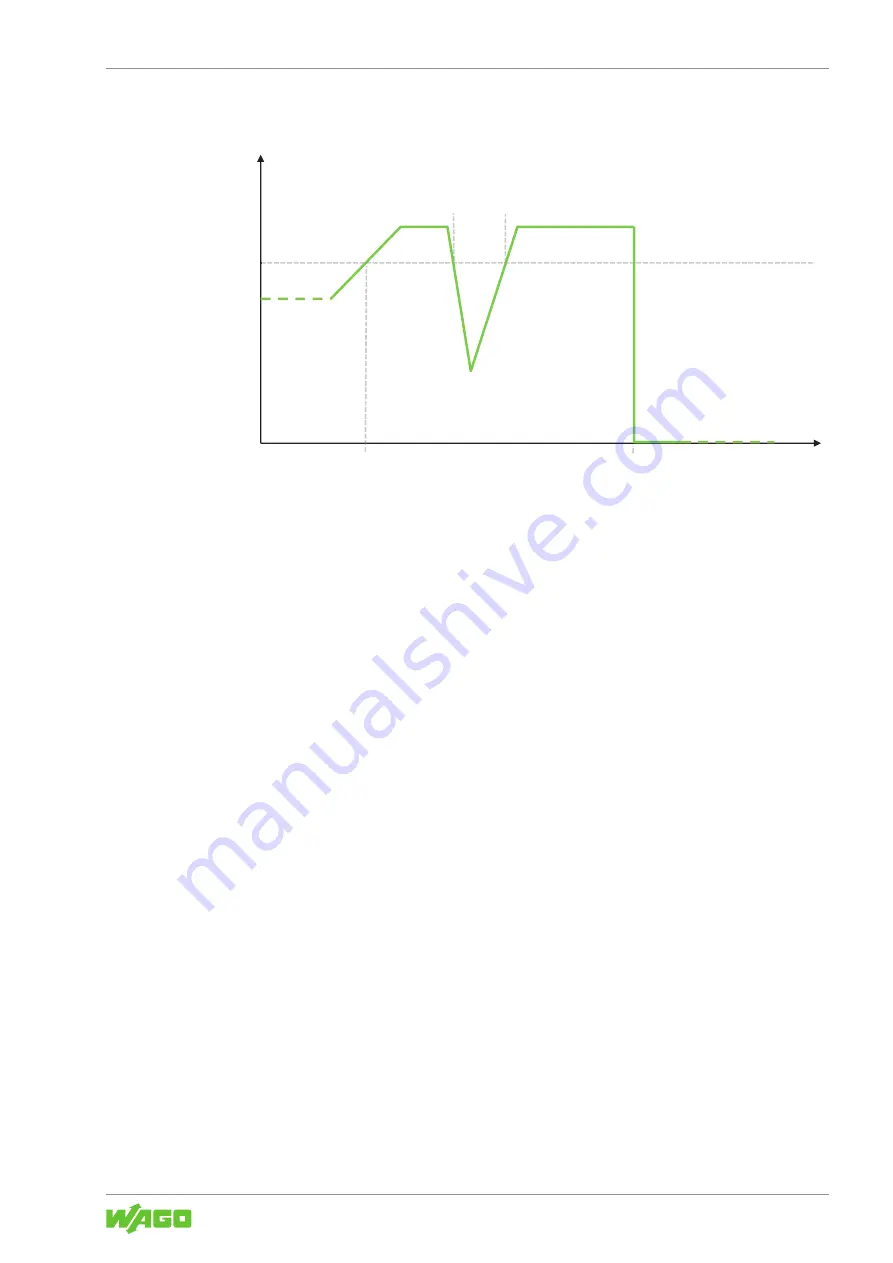

• Digital input

t

I

ECB

t

ECB

t

0

t

1

<100ms

I

OUT

/ I

N

Figure 42: “Electronic Circuit Breaker” Mode

11.6.5 “Latching Shutdown on Thermal Overload” Mode

In this mode, the output voltage is switched off in the event of excessive internal device

temperature. A corresponding “High Device Temperature” warning can, for example, be

transmitted via the WAGO Interface Configuration software or passed to a higher-level

controller via a connected

8

on, manual intervention is necessary. The following options are available for this:

• Communication interface

• Buttons

• Digital input

11.6.6 “Power Boost” Mode

This mode can be used in combination with the following modes:

•

8

•

8

“Constant Current with Latching Shutdown” Mode [

•

8

“Electronic Circuit Breaker” Mode [

In this mode, output current equal to 150 % of the nominal output current is permitted for

5 seconds. The output is then switched off. To switch the output back on, manual inter-

vention is necessary. The following options are available for this:

• Communication interface

• Buttons

• Digital input

In combination with the

8

, the “Power Boost” Mode is

activated again after each pause.