11

5

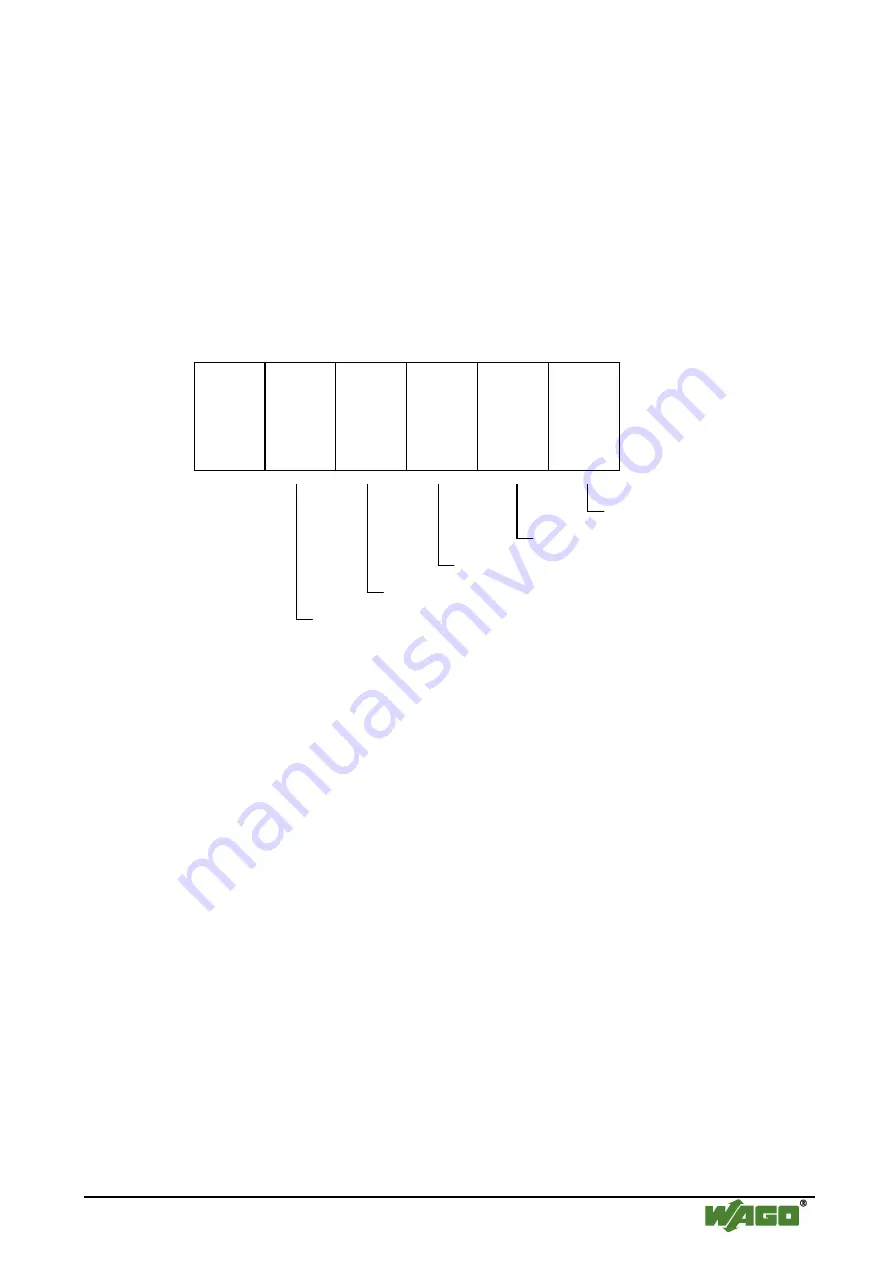

Relation between objects and I/O module

The relation between objects and I/O modules is as follows. Please refer to the Modular I/O System

CANopen 750-337 Manual for the details. The values in parentheses are ones in the manufacturer area; for

example, 0x6000 and 0x2000 are the same value.

0x6000

Digital input

(0x2000)

0x6200

Digital output

(0x2100)

0x6401

Analog input

(0x2400)

0x6411

Analog output

(0x2500)

e.g.)

* Object

Data areas of objects are identified as follows.

Commutation area

0x1000 to 0x1FFFF

Manufacturer area

0x2000 to 0x5FFF

Profile area

0x6000 to 0x9FFF

* NOTE

-

As for the transmission of analog input data, CAN messages can be sent even when tiny variations of

values are found. This may cause an overflow. To avoid this, the transmission of analog input data via

PDOs is deactivated by default. This communication load can be inhibited by the “inhibit time” of the

slave settings. Please refer to 5.2.1 Parameters (POD settings) for the details. For the transmission of

analog input/output data using the object 0x6401 or 0x6411, set the object 0x6423, Analog Input

Global Interrupt Enable, which is to control the transmission of analog input data using PDOs, to 1.

-

For the transmission of analog input/output data using the object 0x2400 or 0x2500, the above setting is

not necessary. The objects 0x2000s to 0x5000s are in the manufacture area and they do not depend on

the above setting.

-

Index 0x6423:Analog Input Global Interrupt Enable

Sub Index0: = [ 1 ] The default value is set to “0”.

WAGO

750-337

8-CH

Digital

Input

2-CH

Analog

Input

2-CH

Analog

Output

8-CH

Digital

Output

2-CH

Analog

Input

0x6401.03

0x6200.01

0x6411.01, 0x6411.02

0x6401.01, 0x6401.02

0x6000.01, 0x6000.02

Summary of Contents for 750-337

Page 4: ......