WAGO-I/O-SYSTEM 750

Fieldbus Communication 133

750-375 PROFINET IO advanced Fieldbus Coupler

Manual

Version 1.1.0

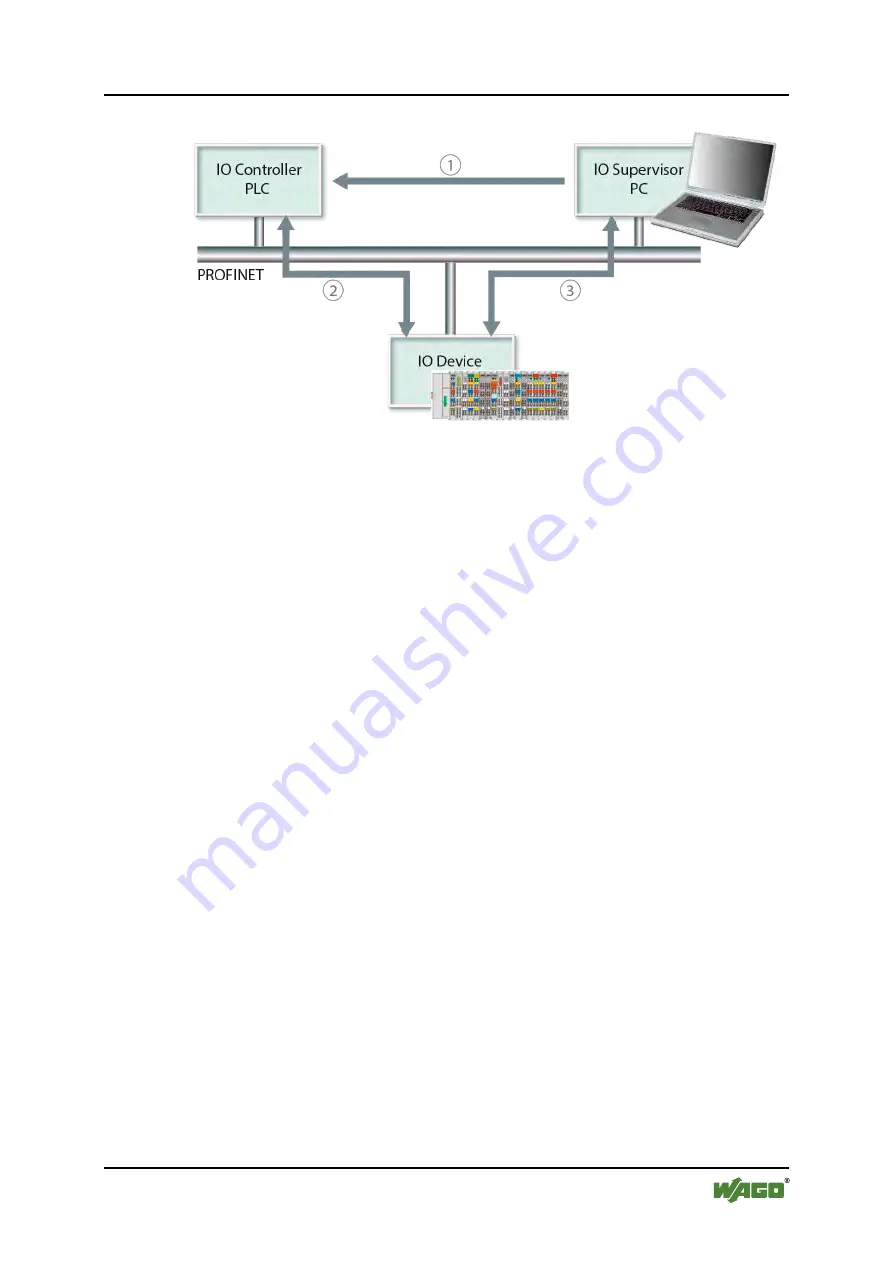

Figure 59: PROFINET principle

•

(1) Use of the IO supervisor is initially only needed temporarily at the

beginning of the configuration of the PROFINET I/O controller. The IO

supervisor (e.g. an engineering station) is typically a programming device

(PD), personal computer (PC) or Human Machine Interface (HMI) device

for commissioning or diagnostics.

•

(2) The IO controller is used to configure IO devices and to exchange

process data and alarms with the IO devices. The IO controller is part of a

higher-level controller (PLC) in the PROFINET network in which the

automation program is running (compared with PROFIBUS that would be

the functionality of a class 1 master). The IO device is a remote IO device

coupled via PROFINET IO (compared with PROFIBUS, this corresponds to

the function of a slave). In a PROFINET network, there is at least one IO

controller and one or more IO devices.

•

(3) The IO supervisor can carry out individual parameterization (iPar) of

specific modules on the IO devices (e.g. safety by means of WAGO SEDI)

directly. It can also take over status and control tasks for the IO devices and

be used for diagnostics of IO devices in the network.

11.2.4

Addressing

The physical MAC address of a device is used to uniquely address a PROFINET

IO field device (IO device) within a network. In addition, each switch port in a

field device is identified by a separate port MAC address, so that a 2-port field

device has a total of 3 MAC addresses.

The additional MAC addresses of the ports are only used in conjunction with

LLDP for topology determination.