Use in Hazardous Environments

•

15

Classification

meeting CENELEC and IEC

WAGO-I/O-SYSTEM 750

I/O Modules

Hydrogen being commonly encountered in chemical plants, frequently the

explosion group IIC is requested for maximum safety.

3.3.3 Unit

categories

Moreover, the areas of use (zones) and the conditions of use (explosion

groups) are subdivided into categories for the electrical operating means:

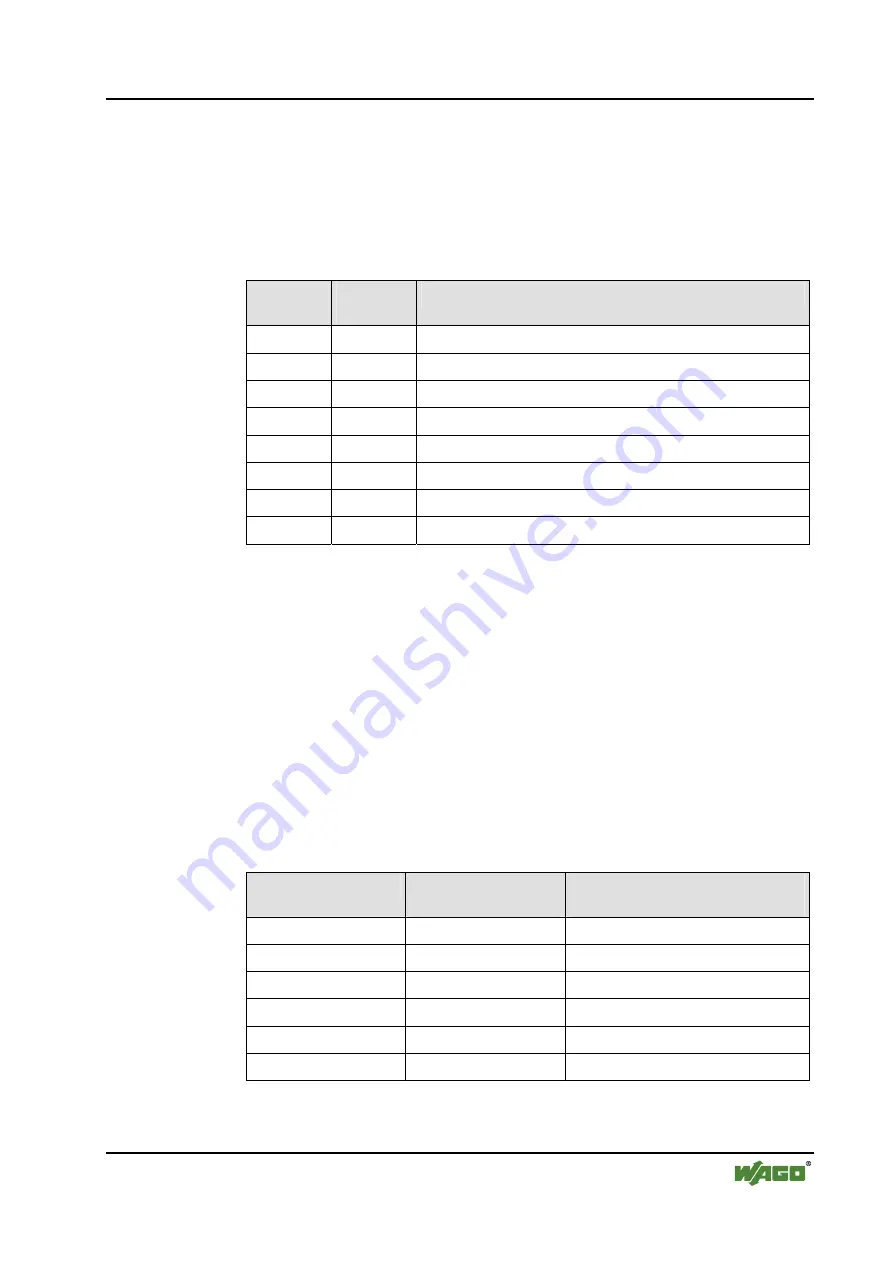

Unit

categories

Explosion

group

Area of use

M1 I Fire-damp

protection

M2 I Fire-damp

protection

1G

II

Zone 0 Explosive environment by gas, fumes or mist

2G

II

Zone 1 Explosive environment by gas, fumes or mist

3G

II

Zone 2 Explosive environment by gas, fumes or mist

1D

II

Zone 20 Explosive environment by dust

2D

II

Zone 21 Explosive environment by dust

3D

II

Zone 22 Explosive environment by dust

3.3.4 Temperature

classes

The maximum surface temperature for electrical components of explosion

protection group I is 150 °C (danger due to coal dust deposits) or 450 °C (if

there is no danger of coal dust deposit).

In line with the maximum surface temperature for all ignition protection types,

the electrical components are subdivided into temperature classes, as far as

electrical components of explosion protection group II are concerned. Here the

temperatures refer to a surrounding temperature of 40 °C for operation and

testing of the electrical components. The lowest ignition temperature of the

existing explosive atmosphere must be higher than the maximum surface

temperature.

Temperature classes

Maximum surface

temperature

Ignition temperature

of the combustible materials

T1

450 °C

> 450 °C

T2

300 °C

> 300 °C to 450 °C

T3

200 °C

> 200 °C to 300 °C

T4

135 °C

> 135 °C to 200 °C

T5

100 °C

>100 °C to 135 °C

T6

85°C

> 85 °C to 100 °C