16

•

Use in Hazardous Environments

Classification

meeting CENELEC and IEC

WAGO-I/O-SYSTEM

750

I/O

Modules

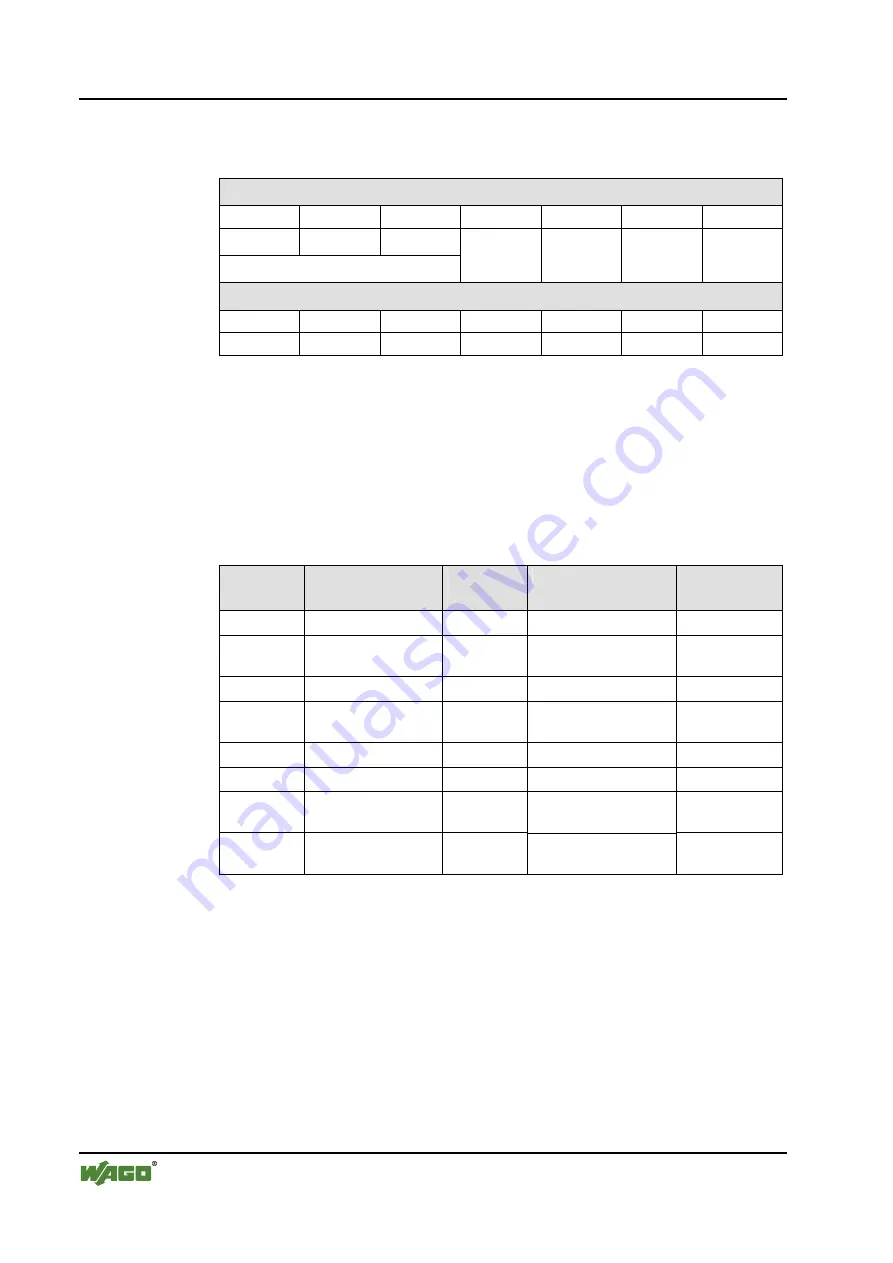

The following table represents the division and attributes of the materials to

the temperature classes and material groups in percent:

Temperature classes

T1 T2 T3 T4 T5 T6 Total

*

26.6 %

42.8 %

25.5 %

94.9 %

4.9 %

0 %

0.2 %

432

Explosion group

IIA

IIB

IIC

Total

*

85.2 %

13.8 %

1.0 %

501

*

Number of classified materials

3.3.5 Types of ignition protection

Ignition protection defines the special measures to be taken for electrical

components in order to prevent the ignition of surrounding explosive

atmospheres. For this reason a differentiation is made between the following

types of ignition protection:

Identifi-

cation

CENELEC

standard

IEC

standard

Explanation

Application

EEx o

EN 50 015

IEC 79-6

Oil encapsulation

Zone 1 + 2

EEx p

EN 50 016

IEC 79-2

Overpressure

encapsulation

Zone 1 + 2

EEx q

EN 50 017

IEC 79-5

Sand encapsulation

Zone 1 + 2

EEx d

EN 50 018

IEC 79-1

Pressure resistant

encapsulation

Zone 1 + 2

EEx e

EN 50 019

IEC 79-7

Increased safety

Zone 1 + 2

EEx m

EN 50 028

IEC 79-18

Cast encapsulation

Zone 1 + 2

EEx i

EN 50 020 (unit)

EN 50 039 (system)

IEC 79-11

Intrinsic safety

Zone 0 + 1 + 2

EEx n

EN 50 021

IEC 79-15

Electrical components

for zone 2 (see below)

Zone 2

Ignition protection “n" describes exclusively the use of explosion protected

electrical components in zone 2. This zone encompasses areas where

explosive atmospheres can only be expected to occur rarely or short-term. It

represents the transition between the area of zone 1, which requires an

explosion protection and safe area in which for instance welding is allowed at

any time.

Regulations covering these electrical components are being prepared on a

world-wide scale. The standard EN 50 021 allows electrical component

manufacturers to obtain certificates from the corresponding authorities for

instance KEMA in the Netherlands or the PTB in Germany, certifying that the

tested components meet the above mentioned standards draft.