Wago Operating Instructions 4PU/4PS/2PU CT 33

Appendix 3

–

Modbus®

A3.1 Communication via the Modbus® Interface

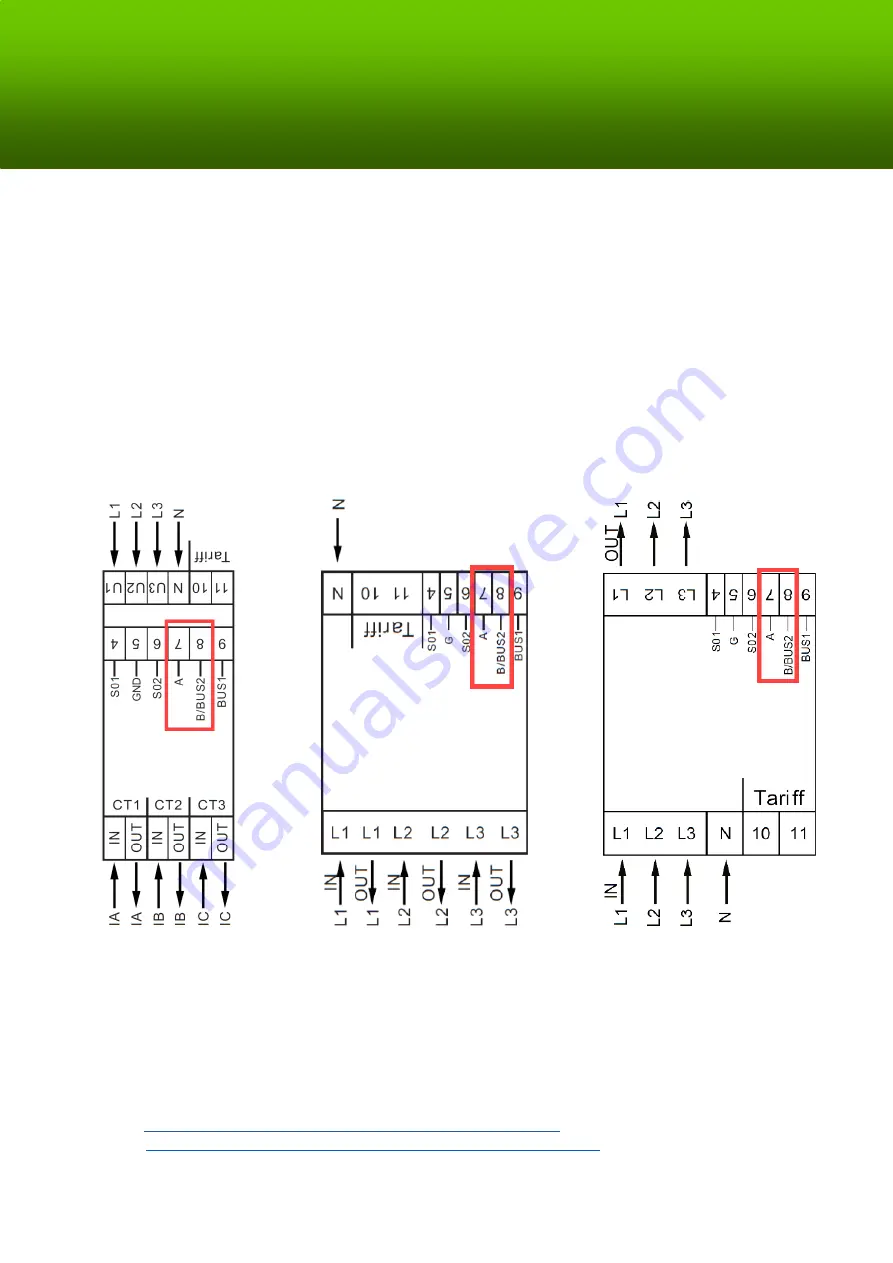

The energy meter can communicate with Modbus

®

master devices on an RS-485 network. Use terminal points 7 and

8 to connect to the RS-485 network.

The factory-set Modbus

®

parameters are as follows:

•

Modbus

®

address 001

•

Baud rate 9600

•

8 data bits

•

Parity: Even

•

1 stop bit

The baud rate can be changed to 115200, 56700, 38400, 19200, 9600, 4800, 2400, 1200, 600 and 300 baud.

Parity can be set to even, odd and none. Data and stop bits cannot be changed.

If you connect the meter via a serial converter (RS-485) for test purposes, please note that due to the incomplete

implementation of the Modbus

®

infrastructure, an additional resistance (120 ohms / 0.25 watts) between terminal

points (7 and 8) must be placed on the meter side.

Please see the Modbus

®

register map on the following pages for information on which registers are used in the meter

and how the data is to be interpreted.

More information on Modbus

®

is available here:

http://www.modbus.org/docs/Modbus_over_serial_line_V1_02.pdf

Protocol:

http://www.modbus.org/docs/Modbus_Application_Protocol_V1_1b3.pdf

4PS

4PU

2PU CT

Summary of Contents for 879-3000 4PU

Page 7: ...WAGO Operating Instructions 4PU 4PS 2PU CT 7 3 2 CE Declaration of Conformity 4PU und 4PS...

Page 8: ...8 WAGO Operating Instructions 4PU 4PS 2PU CT 3 3 MID Declaration of Conformity 2PU CT...

Page 9: ...WAGO Operating Instructions 4PU 4PS 2PU CT 9 3 4 CE Declaration of Conformity 2PU CT...

Page 18: ...18 WAGO Operating Instructions 4PU 4PS 2PU CT 6 4 Process Diagram 4PU 4PS 2PU CT...