144 I/O Modules

WAGO-I/O-SYSTEM 750

750-306 DeviceNet

TM

Fieldbus Coupler

Manual

Version 2.0.0

11.2.5

System Modules

System Modules with Diagnostics

750-610, -611

Power supply modules (750-610 and -611) with diagnostics provide 2 bits in the

input process image to monitor the power supply.

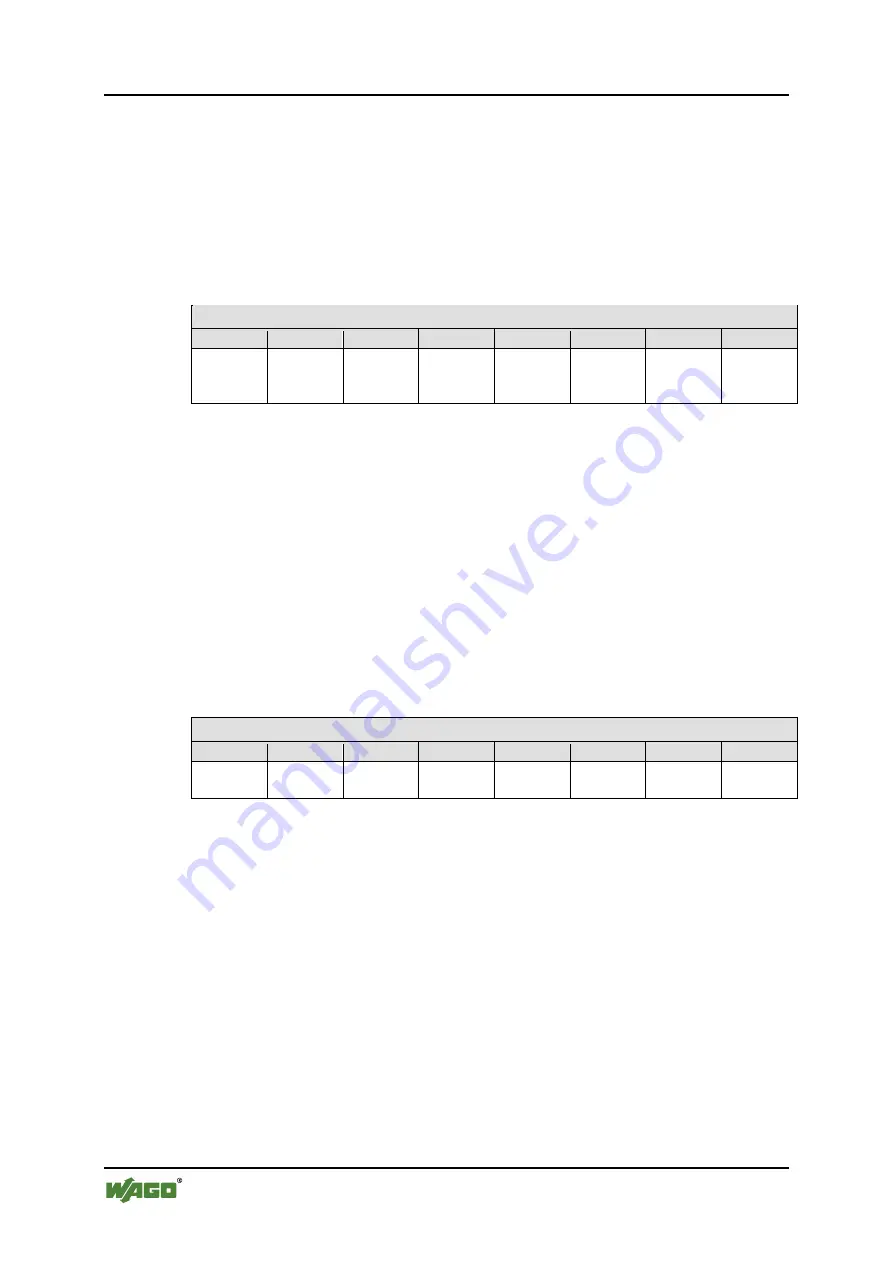

Table 148: Input Process Image, System Modules with Diagnostics

Input Process Image

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

Diagnostic

bit S 2

Fuse

Diagnostic

bit S 1

Voltage

The system modules occupy 2 instances in class (0x65).

Binary Spacer Module

750-622

The binary spacer module (750-622) can operate as a 2-channel digital input

module or output module and, depending on the setting, and occupies 1, 2, 3 or 4

bits per channel.

Accordingly, 2, 4, 6 or 8 bits are occupied either in the input process image or in

the output process image.

Table 149: Input/Output Process Image, Binary Spacer Module

Input/Output Process Image

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

(Data bit

DI 8)

(Data bit

DI 7)

(Data bit

DI 6)

(Data bit

DI 5)

(Data bit

DI 4)

(Data bit

DI 3)

Data bit

DI 2

Data bit

DI 1

The input modules occupy 2, 4, 6 or 8 instances in class (0x65). The output

modules occupy 2, 4, 6 or 8 instances in class (0x65).