21

246.805.201

Date: 2017-09-26

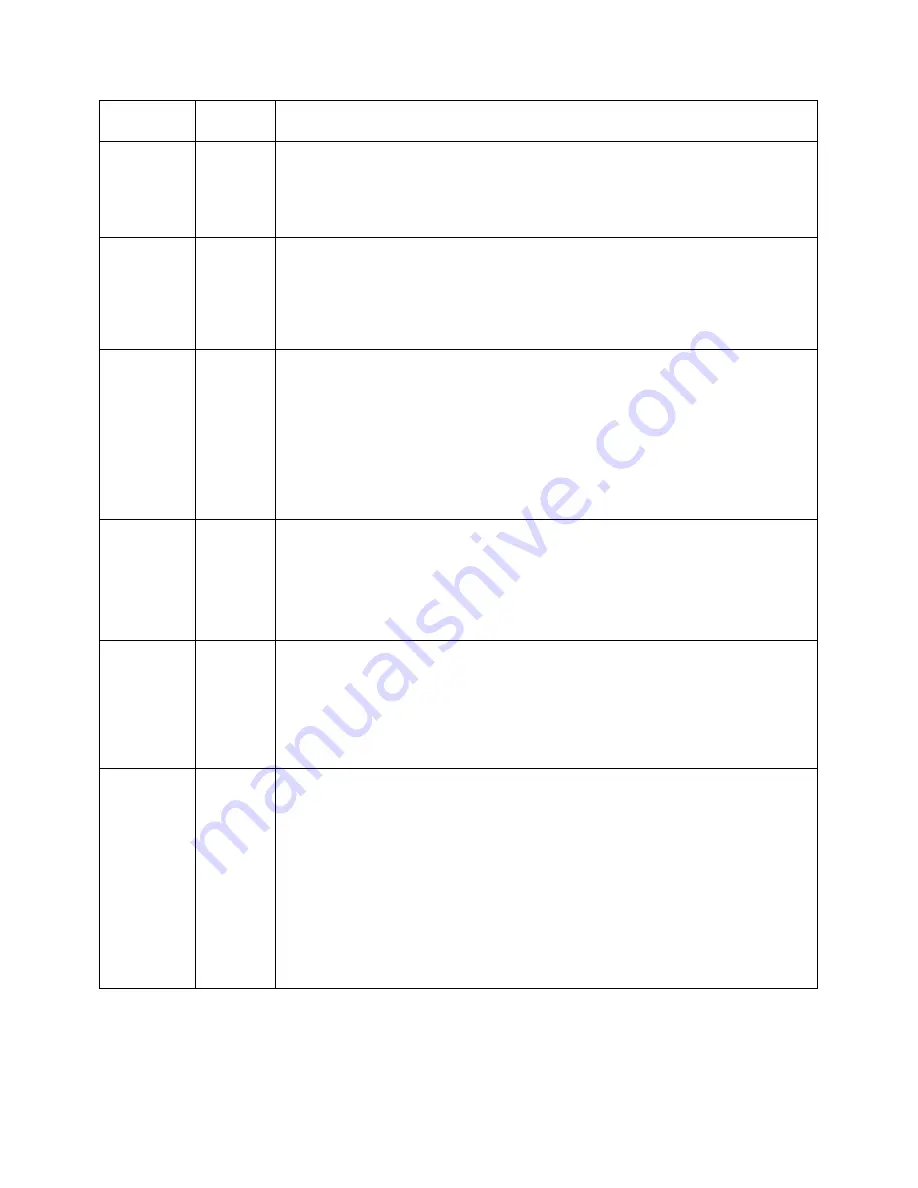

DMX

channel

Function Description

1

Position

rough

This channel controls the position of the winch, with the speed (DMX channel 3).

This rough position works together with the fine position (DMX channel 2).

The rough position and the fine position are multiplied in to a 16 bit channel. The

rough position is the MSB.

2

Position

fine

This channel controls the position of the winch, with the speed set on DMX

channel 3.

This fine position works together with the rough position (DMX channel 1).

The fine position and the rough position are multiplied in to a 16 bit channel. The

fine position is the LSB.

3

Speed

This channel controls the speed and defines the max lifting/lowering speed of the

winch.

The winch runs with the set max speed, but slows down as closing in on the

wanted position.

This channel also works as a main brake; the motor does not run unless the

channel is set above 0%.

The speed-channel can also be used to make soft and slow movements or fast and

sudden movements.

4

Motor

enable

Channel 4 is used as an extra security channel. The value on channel 4 needs to be

between 50 and 55 %, for the motor to run.

All other values make the motor stop.

All other values will also reset any error shown.

All other values will save the current position before a power down.

5

Reset UP

There is a 3s delay on this channel to reduce risk of accidentally resetting the top

position.

Channel 5 is used to manually move the wire up. When channel 5 is set ≥ 10% the

winch will move up until it reaches the limit switch UP. 10 – 100% makes the

motor run up, at variable speed. (10% = low speed – 100% = full speed).

Setting DMX channel 5 to 0 resets the position.

6

Manual

DOWN

There is a 3s delay on this channel to reduce risk of accidentally setting a new

range.

Channel 6 is used to manually move the wire down. When channel 6 is set ≥ 10%

the winch will move down, until it reaches the DOWN limit switch. 10 – 100%

makes the motor run down, at variable speed. (10% = low speed – 100% = full

speed).

The position is reset and a new TAC RANGE is calculated. The new range is the

tacho pulses, between top position set by channel 5 and bottom position set by

channel 6.

The winch should be reset to the top position with channel 5 before the range is

set with channel 6.

Summary of Contents for Winch 50 Double

Page 12: ...12 246 805 201 Date 2017 09 26...