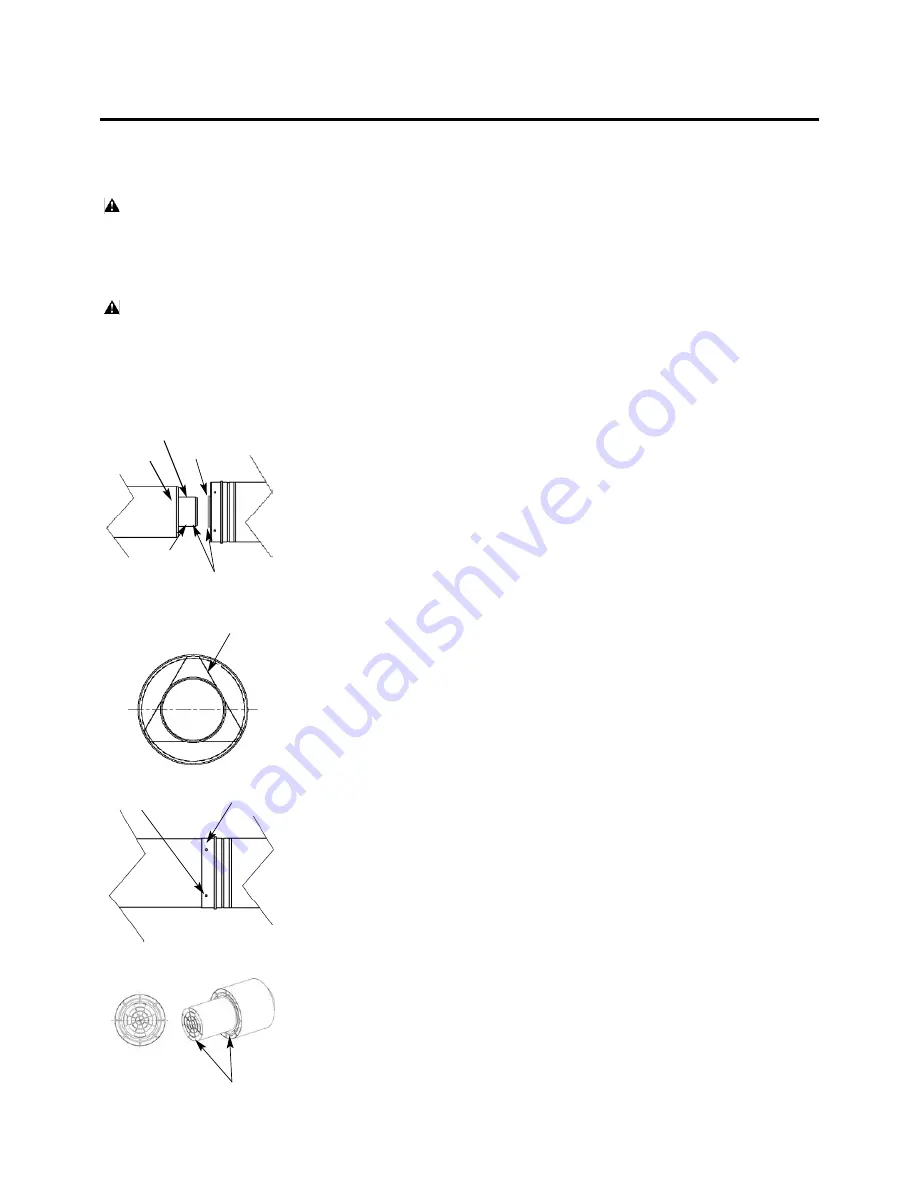

Wipe ends with

alcohol pads

Male End

Female End

Snap Ring

Outer Vent

1” Overlap

Install Self-

Tapping Screws

Before starting the vent installation,

careful planning should be given to the

routing and termination of the vent and

air intake pipe see Figure on page 11

and 12. The vent system requires

mechanical support from the wall,

sufficient to support any incidental

loads on the system. If the wall is not

sufficient enough to support the vent

system, then appropriate additional

framing and/or blocking is required

and appropriate fasteners must be used

to secure the faceplate to the support

members.

Notice: The location must comply

with national and local codes

.

Make a 7-1/4 inches (18.42 cm)

diameter hole at the determined vent

terminal location. Make the hole from

inside the room. The opening inside

the room should be slightly higher than

the outside opening, approximately 2

degrees, so the flue pipe will slope

slightly downward after it is installed.

A minimum pitch of at least ¼” per

foot downward slope must be made

towards the termination. This will

enable condensate to drain from the

flue to the outside and prevent rain and

snow from entering from outside, after

installation.

Remove any insulation from the

opening and add any additional

framing if required.

Joining the vent parts

-

Before joining the sections or fittings

together, use an alcohol pad or cloth to

wipe the joint area of both ends of the

inner pipe. This will remove any

foreign matter. Install the system with

the female ends (ends with the red

seal) pointing away from the

appliance. Insert the male end of the

air intake/vent termination piece into

the female end of the 4”/7” concentric

vent pipe (See Figure on left). In

extremely dry conditions it may be

helpful to moisten the seal with clean

water prior to assembly.

Push firmly on the male end until the

outer jacket has made contact with the

snap ring located in the female end of

the 4”/7” concentric vent pipe section.

When fully assembled, the outer

female end (see Figure to left) will

overlap the male end by approximately

1“ (25.4 mm).

Use the self-tapping screws provided

with the vent kit to connect the two

outer pipes (See Figure on left.).

Position the faceplate into the prepared

hole from the outside.

Measure the thickness of the wall.

The 4”/7” concentric vent pipe

supplied with the vent kit, is designed

for a maximum wall thickness of 8”

(20 cm). If the wall thickness is

greater than 8” (20 cm), an extension

piece or longer length of pipe is

required.

Slide the male end 4”/7” concentric

vent pipe thru the faceplate from

outside the room until it comes to a

stop at the bead. Approximately 8 3/8

inches (20 cm) of the vent terminal

should stick outside the wall.

Ensure the orientation of the air intake

piece is such that the label on the 4“

(10 cm) vent pipe is on top and the

drain hole on the 7“ (17.8 cm) air

intake pipe is at the bottom. After

proper orientation of the vent terminal

and the air intake pipe alignment. The

slots and holes on the termination will

be at the bottom to allow condensation

to escape. See Figure on left.

Slide the second faceplate from the

inside the room on to the 4”/7”

concentric vent pipe till it comes to a

stop on the inner wall of the room.

Ensure that the termination (vent pipe)

is sloped downward towards the

termination.

Secure interior faceplate to outer vent

pipe and inner wall using appropriate

fasteners.

Secure the assembly into the prepared

opening using fasteners as indicated by

sheathing or structural members,

sealing the screw heads with more

caulking.

Alignment

Slots and holes

WARNING: Use UL

approved Category III vent

material only. No other

vent material is permitted.

CAUTION: Follow the

vent manufacturers

installation instructions as

design might vary from

manufacturer to

manufacturer.

The water heater must be installed with an UL approved Category III Stainless Steel appliance vent

adapter and Paloma approved vent termination.

7” Pipe

4” Pipe

Horizontal Vent Installation

13