17

Calibration Failure

For WebMaster

The controller will display a calibration failure if the offset calculated in the

Zero Calibration is outside of the range –20 to 40

mV

or the slope

(mV/ppm) calculated in the One Point Process Calibration is outside of the

range of the nominal mV per 0.1 to 2.0 ppm.

For WDIS:

The acceptable range for the slope (mV/ppm) is the nominal mV per 0.5 to

2.0 ppm. The range of mV for a Zero Calibration is –100 mV to 100 mV.

For W100 or W600 or 900:

The calibration will fail if the adjustment to the gain is outside of 0.2 to

10.0, or if the calculated offset is outside of -40 to 40 mV.

To calculate the nominal slope for your sensor, divide the high end of the

nominal range by -2000. For example, for a 0-20 ppm sensor, the nominal

slope is -2000/20 = -100 mV/ppm.

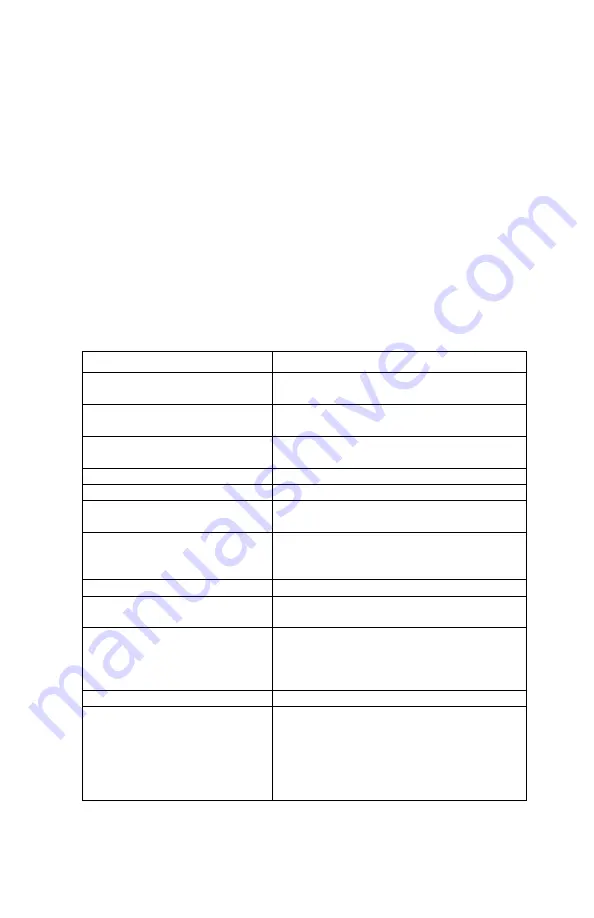

Possible Causes

Corrective Actions

Insufficient conditioning

Wait for the appropriate amount of time

before attempting a calibration.

Insufficient sample flow

Increase flow rate to between 30 and 100

liters per hour

Air bubbles on membrane

Dislodge bubbles. Adjust flow rate higher

if necessary.

Dirty membrane

Clean membrane

Faulty membrane

Replace membrane cap.

High Pressure

Reduce pressure to below 1 atmosphere and

refill cap with electrolyte

No electrolyte fill solution in

membrane cap

Fill membrane cap with electrolyte.

Replace membrane cap if it will not hold

solution.

Faulty sensor

Replace sensor

Faulty analysis equipment or

reagents

Consult test equipment instructions

Sample contaminated with

interfering molecule (refer to

Sensitivity specification in

section 6.0)

Remove source of contamination

Faulty wiring

Check wiring

Faulty controller sensor input

Go to the Sensor Input Page and perform a

self test. If this passes, then the problem is

with the sensor or its wiring. If it fails, then

disconnect the sensor from the circuit board

and try the self test again. If it still fails,

replace the circuit board.