17

Replacement Parts List

When ordering replacement parts, please quote the part number and the description as listed below.

If the part required is not listed below, request the part by description and quote model number and

serial number which is shown on the rating plate.

Griddle

227399

Control Knob - 50°C to 300°C.

229146

Thermostat - 50°C to 300°C.

229353

Overtemp 360°C, 3 Pole.

229145 Switch

4

Pole.

227962 Neon

Green.

227963 Neon

Amber.

228571 Index

Mark

Moulding.

229245 Element

2000W.

228400 Grease

Drawer.

229224

Control Panel Hinge.

Griddle Plate Options

Oven

228082

Oven Top Element 2kW.

228059

Oven Bottom Element 4.5kW.

228704 Door

Spring

Kit.

026160 Terminal

Block

Mains.

227399

Control Knob - 50°C to 300°C.

229146

Thermostat - 50 - 300°C.

229145 Switch

(4-pole).

227962 Neon

Green.

227963 Neon

Amber.

013989 Energy

Regulator.

227398

Control Knob HI/LO Heat.

Convection Oven Only

228938 Oven

Door

Microswitch.

010909 Motor

Capacitor

4µf.

228116 Fan.

019479 Motor.

Replacement Parts List

IMPORTANT:

Only genuine authorized replacement parts should be used for the servicing and

repair of this appliance. The instructions supplied with the parts should be followed

when replacing components.

For further information and servicing instructions, contact your nearest authorized

service branch (contact details are as shown on the reverse of the front cover of this

manual).

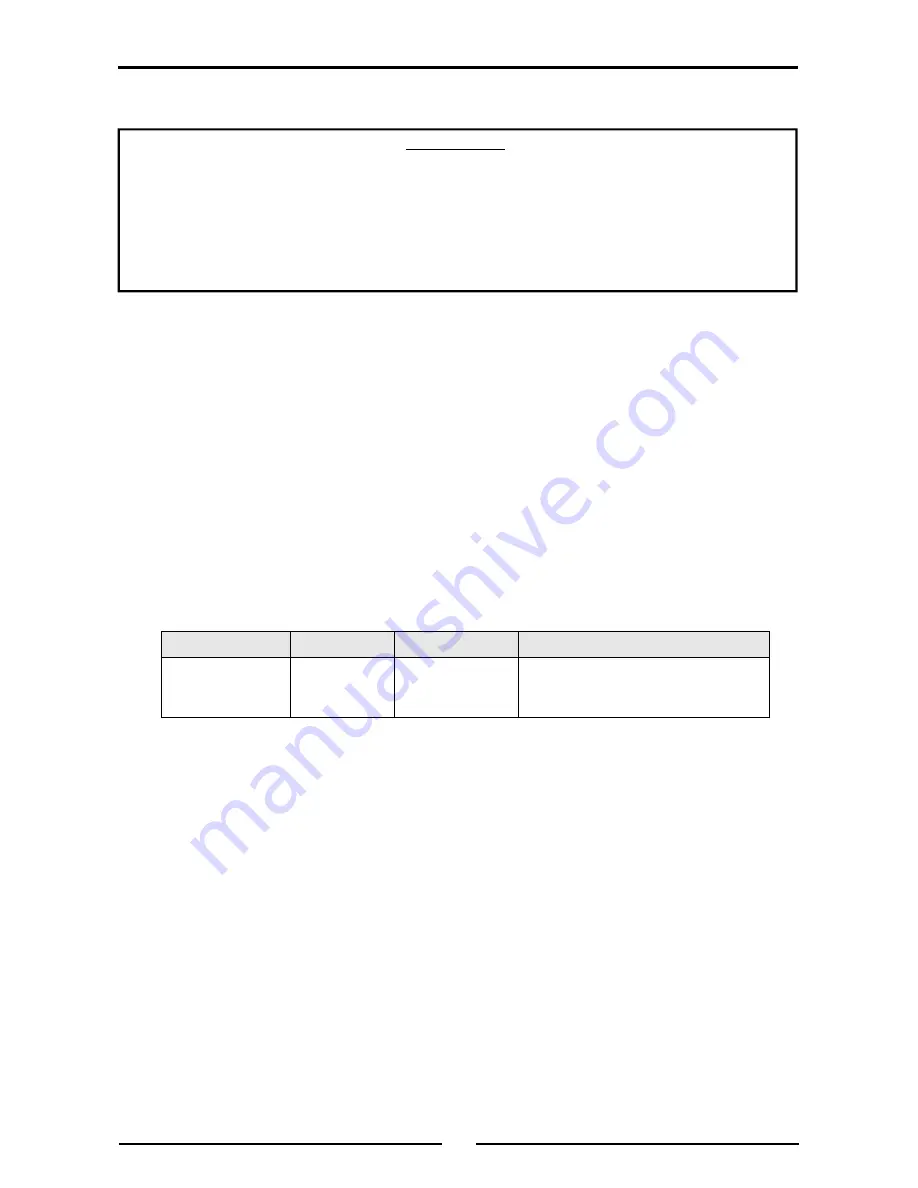

Griddle Plate

Standard

Chromed (-C)

Ribbed

900 mm

229248

229270

ON REQUEST,

Various options (depending on ribbed

section width on LH or RH side).