40

Pro Dry Instruction Manual

|

Walker Filtration

|

www.walkerfiltration.com

Section 7:

Energy Management

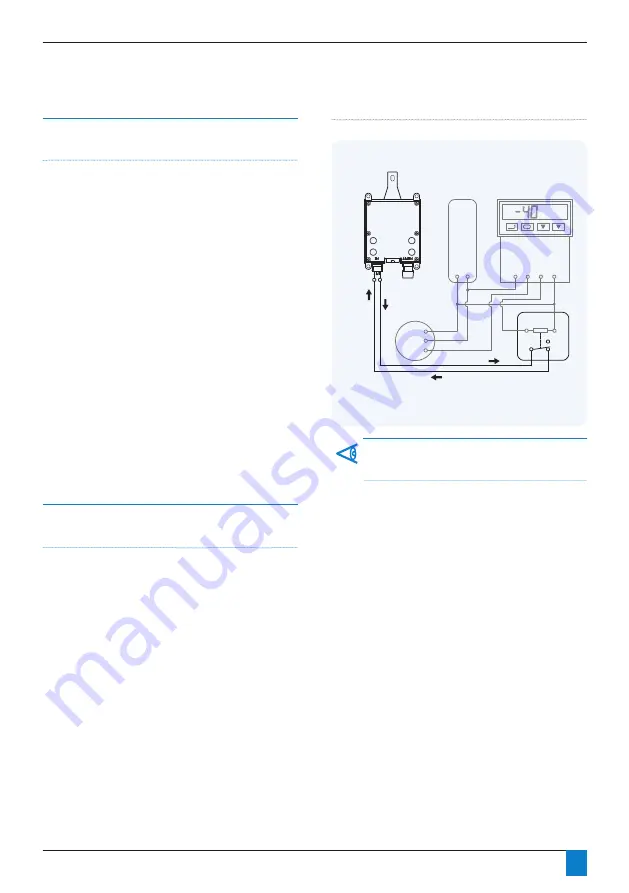

Using a Dew Point Transmitter and Process Controller

for Purge Control

The best option for purge control if the delivered dryness

(pressure dew point) of the air from the dryer is critical. If the

air is deemed dry enough, than the purge can be shut off until

the air’s moisture starts to climb. If the purge is turned off,

care must be taken to ensure that the desiccant beds are not

allowed to wet out too far before the purge is turned back on.

Also, after turning the purge back on, the air’s pressure dew

point may increase a bit before starting to drop again. This

should be taken into consideration to ensure that the air flow

remains sufficiently dry.

It is extremely important to understand that the purge may

only be shut off during periods of low or no demand. This

feature, if used otherwise, can result in permanent damage

to the desiccant beds resulting in loss of drying capacity

and possibly mechanical failure. The cartridges must not be

allowed to become fully saturated at any time.

The following schematic offers an overview of the devices

mentioned as they might be connected for use in controlling

a dryer’s purge function. Please note that specific details

differ between device manufacturers, so in all cases the

manufacturer’s specifications should be adhered to.

Making Connections between a Switching Device &

Dryer EM Contact

Cable / Wire Selection Criteria:

Selected wire should have...

•

at least 2 conductors. More conductors can be useful

in the case of a conductor break. Conductors can be

swapped without having to run new cable.

•

a conductor gauge of no greater than 18 awg is

recommended to fit comfortably into the DIN connector

insert.

• an outside diameter of no greater than 6mm (1/4”). Larger

diameters do not fit well into the cable gland of the EM

DIN connectors.

•

an insulation type compatible with the environment that

it will be run in.

Figure 7.5: Using process controller

DRYER

CONTROLLER

DC POWER

SUPPLY

ELECTRONIC

PRESSURE SWITCH

RELAY

* Normally Closed, open to turn purge off

PIN 1 (puts out

+5 VDC signal)

PIN 2

SIGNAL BACK

SIGNAL OUT

N.C.*

N.O.

N.C.*

N.C.*

N.O.

* Normally Closed, open to turn purge off

MANUAL SWITCH

(Field Installed)

DRYER

CONTROLLER

PIN 1 (puts out +5 VDC signal)

PIN 2

SIGNAL BACK

SIGNAL OUT

* Normally Closed, open to turn purge off

MANUAL SWITCH

(Field Installed)

DRYER

CONTROLLER

PIN 1 (puts out +5 VDC signal)

PIN 2

SIGNAL BACK

SIGNAL OUT

CO

M

SI

GN

AL

O

UT

+

VD

C

+

VD

C

-V

DC

(C

O

M

)

DRYER

CONTROLLER

* Normally Closed, open to turn purge off

PROCESS

CONTROLLER

DC POWER

SUPPLY

DEW POINT

TRANSMITTER

RELAY

PIN 1 (puts out

+5 VDC signal)

PIN 2

SIGNAL BACK

SIGNAL OUT

SIGNAL

+VDC

COM

N.C.*

N.O.

CO

M

SI

GN

AL

O

UT

SI

GN

AL

IN

+

VD

C

+

VD

C

-V

DC

(C

O

M

)

This setup is for example only. This configuration can be

ammended, depending on application.