800-WMAGNET

9 of 33

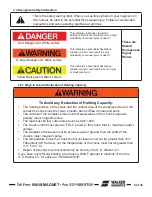

3.1.7 Connecting Optional Features

SMART-D chuck controls are equipped with three optional features, Current Sensing, Part Release and

Lockout. These features enable the chuck control to work with external equipment such as machine controls or

a PLC. Refer to the “Operation” section 4 of this manual for using of these features.

3.1.8 Current Sensing

This control is equipped with a current sensing feature that monitors the current flowing to the chuck and

indicates when this current has reached a predetermined value. The current sense relay is a “Form C” dry

contact type. The connections are at J4: Pin 6 is common, Pin 7 is the N. O. contact, and Pin 8 is the N. C.

contact. The rating of the contacts are 10 A @ 125 VAC, 5 A @ 250 VAC, and 5 A @ 30 VDC. See Figure 5 5

for locations.

3.1.9 Part Release

The part release relay energizes and de-energizes with the chuck. It is the same type as the current sense

relay. The connections are at J4: Pin 3 is the common, Pin 4 is the N. O., and Pin 5 is the N. C. contact. See

Figure 5 5 for locations.

3.1.10 Lockout

A Lockout feature is supplied with this control, which prevents anyone from accidentally changing the settings

while machining is in progress. There are two connections for lockout. The first is to supply 115 VAC to J4,

terminals 1 and 2. The second is to sink the positive voltage at J5, terminal 8. This is done using a dry contact

connected to terminal 8 (lockout) and terminal 13 (GND) on J5*. See Figure 5 5 for locations.

* When using lock-out, JP2 jumper must be removed.

3.1.11 Energizing the System

Inspect the conduit and wire installation. Verify that all wiring connections are correct and secure, paying

particular attention to the ground connections. Thoroughly read the “Operating Instructions” section 4 prior to

energizing any equipment.

Close all breakers and disconnects upstream of the chuck control. Close the door (on models equipped with

enclosures) and put the chuck control disconnect switch in the “ON” position. When power is first applied, the

chuck control will initialize itself in the “Release Mode”. The “Release” indicator light on the remote unit will be

lit and the current sense relay open. The system is ready for operation. No power is applied to the chuck.

3.2 Control Mounting Guidelines

1. When any control (power section) is removed from its original enclosure or shipped without an enclosure and installed in a customer

supplied enclosure, the following specifications must be met.

a. The air surrounding the panel on which the parts are located should not exceed 120° Fahrenheit.

b. The air temperature must be measured:

1) With the control in the Full holding position;

2) After the control has been in operation for 30 minutes; and

3) With the chuck holding the largest load to be used.

Summary of Contents for IMI Smart-D Series

Page 18: ...800 WMAGNET 18 of 33 5 6 Smart 75 100D Panel Layout Figure 5 1 Smart 75 100D Panel...

Page 19: ...800 WMAGNET 19 of 33 5 7 Smart 20 30 50D Panel Layout Figure 5 2 Smart 20 30 50D Panel...

Page 20: ...800 WMAGNET 20 of 33 5 8 Smart 7 10 15D Panel Layout Figure 5 3 Smart 7 10 15D Panel...

Page 21: ...800 WMAGNET 21 of 33 5 9 Smart 3 5D Panel Layout Figure 5 4 Smart 3 5D Panel...

Page 22: ...800 WMAGNET 22 of 33 5 10 Main PC Board Figure 5 5 Main PC Board...

Page 30: ...800 WMAGNET 30 of 33 5 3 Remote Enclosure Dimensions Figure 5 12 Remote Enclosure BB 8783...

Page 31: ...800 WMAGNET 31 of 33 5 4 Remote Wiring Connections Figure 5 13 Remote Wiring Connections...

Page 34: ...1 800 W MAGNET WWW WALKERMAGNET COM 900632 A 07 21...