14

Walker Magnetics, Inc., NEO Permanent Lifting Magnets

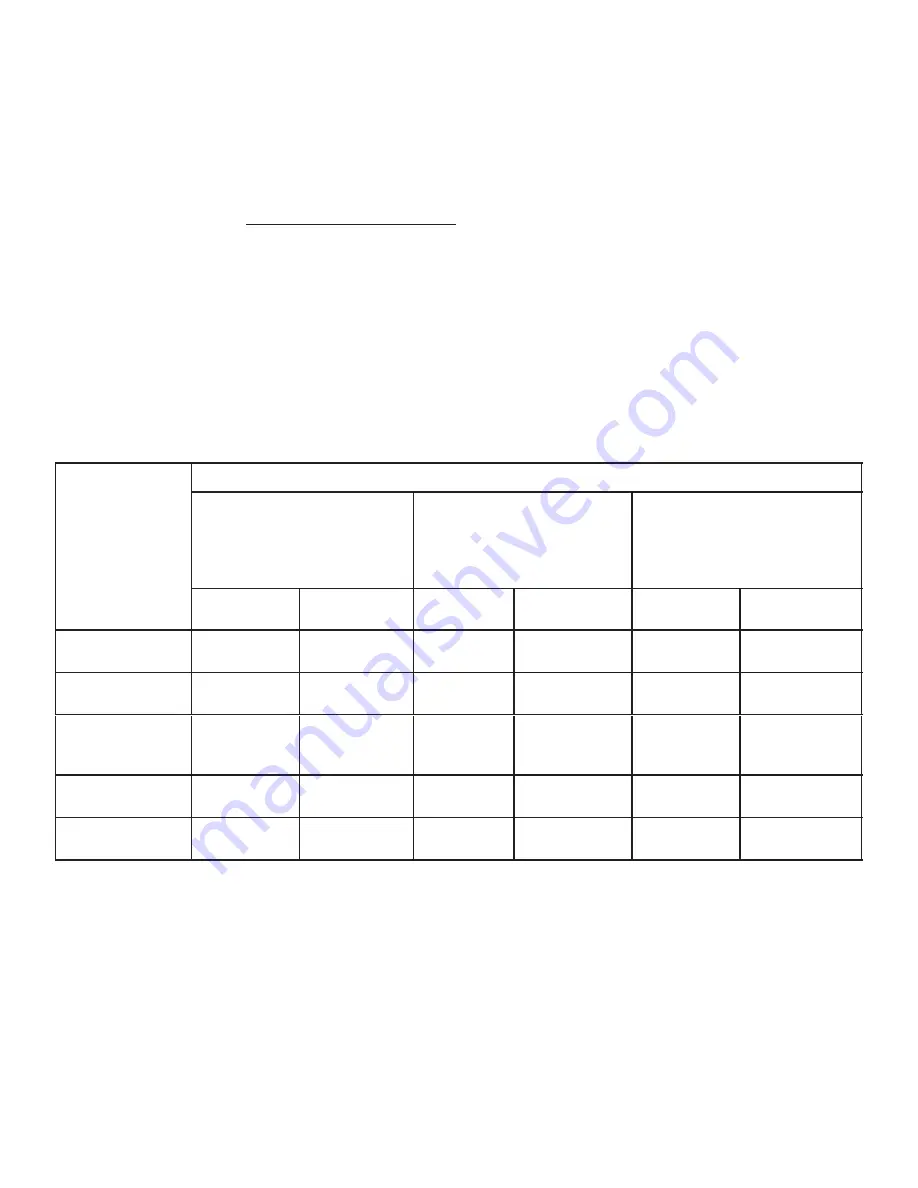

NEO-250

LIFTING GUIDELINES

(PLATE)

NEVER EXCEED EITHER THE MAXIMUM WEIGHT OR SIZE SHOWN

FOR EACH LOAD THICKNESS AND TYPE OF SURFACE CONDITION

LOAD

THICKNESS

Inches

TYPE OF SURFACE CONDITION

CLEAN & SMOOTH

Similar to a Flat

(32 micro-inch RMS)

Ground Surface

.000” Max. Air Gap

RUST OR SCALE

Similar to a Flat Hot Rolled

Steel Surface

.010” Max. Air Gap †

(.254mm)

IRREGULAR OR ROUGH

Similar to a Flat Smooth

Cut File

.020” Max. Air Gap †

(.508mm)

Maximum Load

Pounds

s

Maximum Length

Inches

Maximum Load

Pounds

Maximum Length

Inches

Maximum Load

Pounds

Maximum Length

Inches

2 1/2” & above

(64mm & above)

550

(250kg)

-

360

(165kg)

-

230

(105kg)

-

*1”

(25.4mm)

450

(205kg)

48x32

(1.2 x .8m)

305

(140kg)

44x24

(1.1 x .6m)

205

(95kg)

30x24

(.75 x .6m)

*1/2”

(12.7mm)

275

(125kg)

48x40

(1.2 x 1.0m)

220

(100kg)

48x30

(1.2 x .75m)

160

(73kg)

36x30

(.9 x .75m)

*3/8”

(9.5mm)

170

(77kg)

48x32

(1.2 x .8m)

130

(60kg)

36x32

(.9 x .8m)

107

(49kg)

42x24

(1.05 x .6m)

*1/4”

(6.4mm)

90

(42kg)

48x26

(1.2 x 6.5m)

65

(30kg)

36x24

(.9 x .6m)

55

(25kg)

30x24

(.75 x .6m)

Values shown are for maximum rated capacities when operating instructions and warnings are

followed.

VALUES ARE BASED UPON AISI 1020 STEEL

Higher alloy steels and other magnetic materials will require further reductions of these rated

capacities (See page 11 for the Guidelines for the reduction of the Rated Lifting Capacities.)

NEVER LIFT ANY LOADS WITH ANY DIMENSION GREATER THAN 60

INCHES (1.5 METERS)

OR WITH A THICKNESS LESS THAN 1/4” (6.4 mm)

† Air Gap = nonmagnetic separation between magnet’s lifting surface and load.

* Lifting capacity affected by peel and thickness. See notes 2 & 4 in the “Important

Facts” and “Recommended Lifting Procedures” (See pages 6, 7 and 10).