Maintenance Instructions

LUBRICATION

36

LUBRICATION

Proper lubrication is an important maintenance pro-

cedure. It reduces wear and makes the machine

quieter and easier to operate.

Engine Oil

Engine Break-In Oil

No special break-in oil is required. The engine is ser-

viced with 10W-30, Service Class SG oil from the

factory. The oil should be changed after the initial

engine break-in period of 5-8 hours. Thereafter,

change oil after every 50 hours of operation.

Checking Engine Crankcase Oil Level

Check the engine crankcase oil level before use and

after each 8 hours of continuous operation.

IMPORTANT: The importance of checking and

maintaining the proper crankcase oil level cannot be

overemphasized. Check the oil level BEFORE

EACH USE.

1.

Park the mower on a level surface with the

engine stopped. Also, make sure the engine is

cool and oil has had time to drain into the sump

[allow at least five (5) minutes after stopping

the engine].

IMPORTANT: NEVER check or add oil with the

engine running.

2.

Before removing the dipstick, clean the area

around the dipstick to keep any dirt or debris out

of the engine.

3.

Remove the dipstick, wipe off with a clean rag,

then reinsert the dipstick into the tube and press

all the way down.

4.

Remove the dipstick again and check the oil

level on the dipstick. The oil level should be

within the “Operating Range” on the dipstick

(between the LOW mark and the FULL mark).

IMPORTANT: DO NOT operate engine without

sufficient oil supply in the crankcase. DO NOT

operate with oil level below the LOW mark or

above the FULL mark on the dipstick.

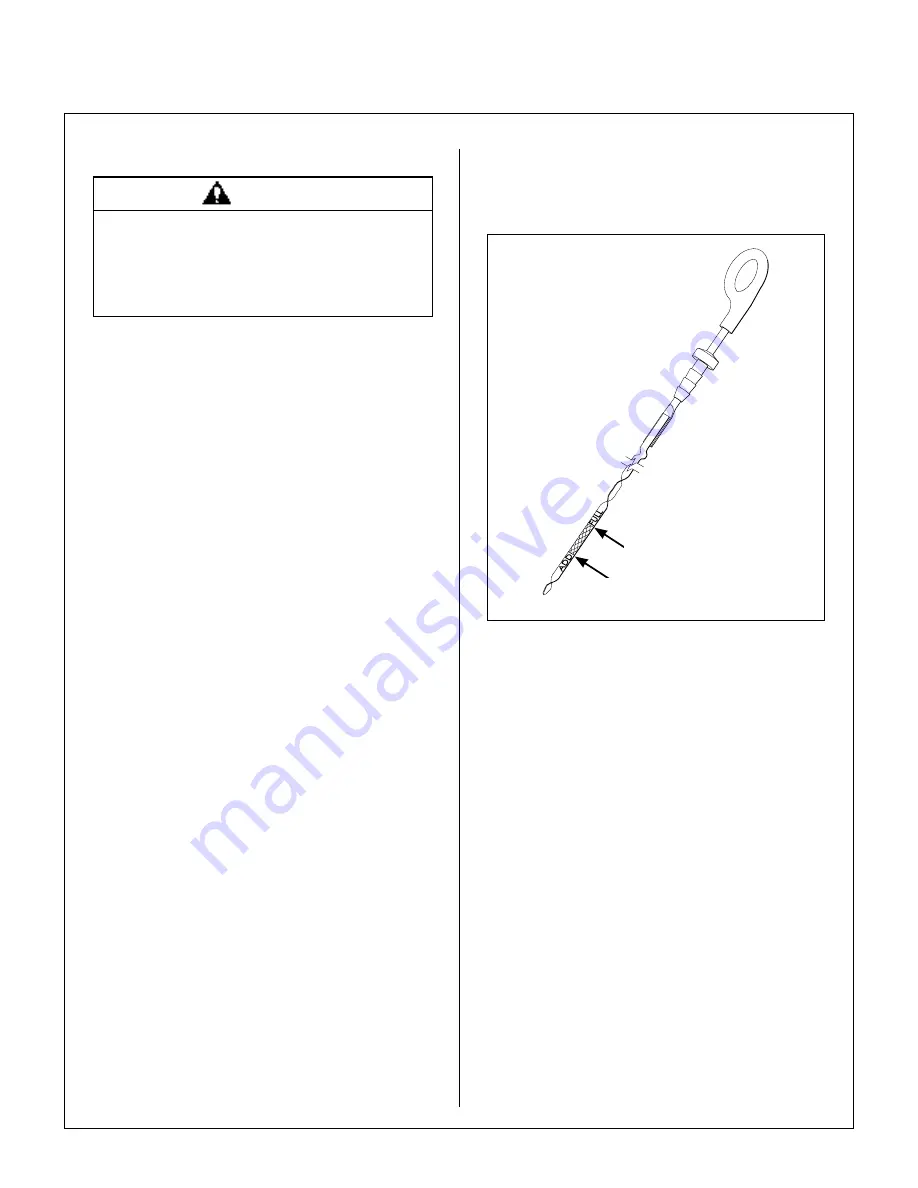

Dipstick Operating Range

5.

If additional oil is needed, refer to

Specifications

for proper crankcase lubricant. Fill to the FULL

mark.

IMPORTANT: DO NOT overfill crankcase [oil

above FULL level] as this CAN result in engine

overheating, loss of power, and possible

engine damage.

Changing Engine Crankcase Oil/Oil Filter

Change the engine crankcase oil after every 50

hours of operation and the oil filter after every 100

hours of operation as follows:

1.

Park the mower on a level surface with the

engine stopped. The engine oil should be

warm before draining. If not warm from opera-

tion, start the engine and run a few minutes to

warm the oil.

2.

Before removing the dipstick, clean the area

around it to keep any dirt or debris out of the

engine.

WARNING

DO NOT attempt to lubricate the machine

with the engine running. Disengage the

PTO clutch, shut off the machine, and re-

move the ignition key.

{

LOW

Mark

FULL

Mark

Operating

Range