Maintenance Instructions

LUBRICATION/CLEANING

47

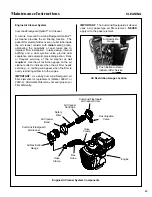

Oil Filter

Guard

Oil Drain

Plug

Oil Filter

Transaxle Oil Drain Plug, Filter, and

Guard Location

(Shown with Deck Support Arms

Removed for Clarity)

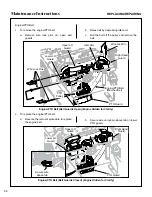

3. Reinstall drain plugs.

4. Remove the oil reservoir hose attached to the

elbow on top of the transaxles and remove the

elbows to access the oil fill openings.

5. Fill the transaxles with 20W-50 (API Service

Class SL or higher) oil through the opening

where the elbows were. Fill up to the opening.

6. Before reinstalling the elbows, screw the lock-

ing nut on the elbows down until they are snug

(the o-ring on the elbow will be to the bottom of

the o-ring groove).

7. Reinstall the elbows. When the elbow begins to

be snug, position the elbow as it was when re-

moved and tighten the locknut.

8. Fill reservoir to 1/4-1/2 in. (6-13 mm) with

20W-50 (API Service Class SL or higher) oil.

9. Start and drive the unit for 1 - 2 minutes.

10. If the transaxles sound noisy or have poor steer-

ing response, recheck oil level in both transax-

les by removing the elbows (check oil level at fill

opening).

11. If oil needs to be added refer back to steps 4-10.

CLEANING

CAUTION

If a pressure washer is used on the ex-

posed working parts, avoid water on the

electrical parts and the engine cooling sys-

tem.

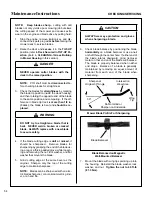

Engine Air Cooling System

To prevent engine overheating and possible engine

damage, clean grass clippings, chaff and dirt from

the rotating engine air intake screen

every 8 hours

of operation. In certain mowing conditions (dry

grass, leaves, tree “cotton”, etc.) it may be neces-

sary to check and clean this area several times each

day to prevent engine overheating. Also, visually

check inside cylinder head shroud and between cyl-

inder head fins for material packed in this area which

would prevent cooling airflow; remove shroud and

clean as required.

IMPORTANT:

Yearly or every 100 hours, remove

engine cooling shroud and clean cylinder head cool-

ing fins to prevent overheating. Make sure cooling

shroud is reinstalled properly.

Rotating Engine Screen

Keep Engine Screen Clean