Assembly and Installation

A16

8

Assembly and Installation

ASSEMBLY

Follow these steps to assemble the spray tank prior

to installing it on the tractor. These steps must be

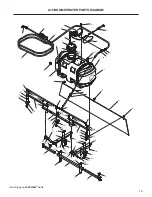

1. Install the left (P/N B029, #30) and right (P/N

B030, #38) Tank Supports on the bottom of the

tank. Install them with the single hole on the

side of the channel facing toward the front and

to the outside as shown in the parts diagram.

Use four (4) F091 5/16” x 5/8” hex bolts.

DO

NOT TIGHTEN ANY HARDWARE UNTIL

DIRECTED.

2. Install the Rear Support Brackets and Support

Tubes. The A16 ships with support brackets to

mount on most compatible decks. Differences

in the carrier frames require additional hard-

ware on a few of the decks (DS52, DS60, and

DS62). See the appropriate following section

for these decks.

NOTE:

The DC52R and the DM52A use a

different carrier frame than the DS52 and

therefore do not required additional mounting

hardware.

● If you are installing on a DS52 or DS60,

● If you are installing on a DS60, skip to the

section,

For All Compatible Decks (other than the

DS52, DS60, and DS62)

Use the two (2) included Rear Support Brack-

ets (P/N B028, #31).

a. Using two (2) F034 5/16” x 3/4” flange bolts

and F009 nuts mount each Rear Support

Bracket to the left and right Tank Supports

as shown in the parts diagram

.

b. Install the Support Tube (P/N B025, #35)

on the left and right Tank Supports in front

of the Rear Support Brackets using the two

U-bolts (B035, #34) and four (4) F427 5/16”

flange nuts into the appropriate set of

holes.

-

For the 42” and 48” carrier frames

, use

the

rear

set of holes closest to the Rear

Support Brackets.

-

For the 52” carrier frame

, use the

front

set of holes.

The tube should be installed with the holes

in the

vertical position

. The tube should

be positioned with

2-1/8” extending past

the Tank Supports on each end.

Tighten

all hardware installed.

c. Invert the unit, slide the left (P/N B027,

#33) and right (P/N B034, #37) Support

Tube Assemblies into the end of the Sup-

port Tube in a fully extended position.

d. Install the locking pins (P/N B026, #32) into

the tubes.

e. Continue the assembly with Step 3 install-

For DS52 and DS62

The following components must be purchased

separately to mount the sprayer on these

decks:

● Two (2) x B037 Mounting Bracket, 52/62

The included Rear Support Brackets (P/N

B028, #31) are not used with these decks.

a. Using two (2) F034 5/16” x 3/4” flange bolts

and F009 nuts mount each B037 Mounting

Bracket to the left and right Tank Supports.

(These brackets will be in the same posi-

tion as the #31 brackets in the parts draw-

ing.)

b. Install the Support Tube (P/N B025, #35)

using the holes immediately in front of the

Rear Support Brackets on the left and right

Tank Supports with (2) two U-bolts (B035,

#34) and four (4) F427 5/16” flange nuts.

The tube should be installed with the holes

in the

vertical position

. The tube should

be positioned with

2-1/8” extending past

the Tank Supports on each end.

Tighten

all hardware installed.