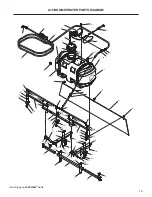

A16

Parts Lists and Diagrams

15

ITEM PART

DESCRIPTION

NO.

NO. NO.

REQ’D

ITEM PART

DESCRIPTION

NO.

NO. NO.

REQ’D

Use only genuine

Walker

®

parts.

Parts Lists and Diagrams

A16 BOOM SPRAYER PARTS LIST

Pump, Hose and Wand Components

1

B017

Spray Wand W/Tip (#43238)

1

2

B010

Hose Clamp (3/8)

5

3

B020

Sump Strainer (#43258)

1

4

B021

Poly Straight Fitting (3/8) (#43182)

1

5

B007

Elbow, Poly 3/8 (#43183)

1

6

B003

Pump (#43178)

1

7

B008

Poly Tee (3/8) (#43235)

1

8

B022

In-Line Valve (#43014)

1

9

B011

Poly Tee Hose, 3/8 (43013)

1

10

B012

End Tip Fitting W/Nut (#43011)

2

11

B013

Tee Tip Fitting W/Nut (#43192)

1

12

B009

Hose (3/8 x 20/Black)

1

Tank Components

13

B002

Cap, Tank (#43175)

1

14

B002-1

Rubber Gasket (#ST43882)

1

15

B019

Hose Clip (#43191)

1

16

B018

Spray Wand Holder (#43130)

1

17

B001-1

Tank, 25 Gallon

1

18

5800-9

Decal, Walker Round (4-3/4")

2

19

B022-1

Decal, Caution (#43239)

1

20

B002-2

Cap, Drain W/Washer

1

Electrical Components

21

B004

Wire Harness (#43472)

1

22

B005

Harness/Batt Conn(ST43483)

1

Frame Mount

23

B036-3

S-Hook, Wind Screen

3

24

B036-1

Wind Screen

1

25

B014-1

Spray Tip

3

26

B033

Boom Extensions (#43170)

2

27

B015

Tip Strainer/Check Valve (#43016)

3

28

B036-2

Support, Wind Screen

3

29

B016

Cap Nut, Tip Fitting (#43012)

3

30

B029

Tank Support, LH (#43320)

1

31

B028

Support Bracket, Rear (#43319)

2

32

B026

Locking Pins (#43317)

2

33

B027

Support Tube Assy, LH (#43318)

1

34

B035

U-Bolt (#43323)

2

35

B025

Support Tube (#43316)

1

36

B031

Boom Supports (#43168)

2

37

B034

Support Tube Assy, RH (#43322)

1

38

B030

Tank Support, RH (#43321)

1

39

B032

Main Boom (#43169)

1

Fasteners

F009

5/16-18 Whiz Locknut

4

F020

5/16-18 ESNA Nut

4

F025

10-24 x 3/8 PPHMS

2

F034

5/16-18 x 3/4 Hex Bolt

4

F091

5/16-18 x 5/8 Hex Bolt

4

F093

5/16-18 x 1 Hex Bolt

4

F170

5/16 x 1 x 7/64 Flat Washer (Zinc Plate)

3

F306

3/8-16 x 3/4 Hex Bolt

2

F396

10-24 x 1-1/4 PPH Bolt

4

F427

5/16-18 Flange Nut

6

F433

5/16-18 x 1/2 Carriage Bolt

2

F570

3/8-16 Flange Top Lock Nut

3

F646

3/8-16 x 3/4 Serrated Hex Bolt

3

Service Parts (Not Shown)

B017-1

Spray Wand Tip

B003-1

Pump Head