Operating Instructions

32

5. Stop ground travel by pulling both steering le-

vers backward to the

NEUTRAL-PARK

position

(trac tor not moving) and then moving the FSC

lever to the

NEUTRAL-PARK

position.

NOTE:

If the tractor creeps forward or back-

ward with the FSC lever in the

NEUTRAL-PARK

position, the transmission control needs to be

adjusted. Refer to

ADJUSTMENTS

for

Step 3 -

Neutral Position Adjustment

in the

Maintenance

Instructions.

ENGAGING THE BLADE DRIVE

1. Set the engine throttle at about 1/3 speed.

DO

NOT attempt to engage the blade clutch at

high engine speeds.

This will drastically short-

en drive belt life. Use only moderate engine

speed when engaging the blade clutch.

2. Engage the blade clutch by moving the blade

clutch lever forward

SLOWLY.

For disengage-

ment, move the blade clutch lever backward

SLOWLY.

CAUTION

An operator presence switch (seat switch)

will cause the engine to stop if the blade

clutch is engaged and the operator is not in

the seat. The function of this switch should

be checked by the operator raising off the

seat and engaging the blade clutch; the en-

gine should stop. If the switch is not work-

ing, it should be repaired or replaced be-

fore operating the mower. DO NOT

disconnect the safety switches; they are

for the operator’s protection.

IMPORTANT:

DO NOT

engage the blade clutch

when transporting the mower across drives, side-

walks, loose materials, etc.

DO NOT engage the

blade clutch with the PTO shaft disconnected

(the mower deck removed from tractor).

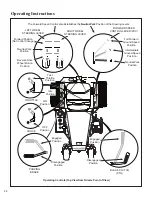

Engaged

Position

Blade Clutch Engaged

Disengaged

Position

Blade Clutch Disengaged

CAUTION

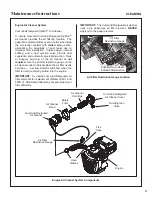

If the cutting blades strike a stationary ob-

ject while mowing, stop the mower imme-

diately, disconnect the spark plug wires, lift

the deck, and inspect the deck and blades

thoroughly for damage. Make sure that the

blade timing has not been dis turbed (the

blades should be at 90 degrees to each

other). Refer to REPLACING/RE PAIRING

the Blade Overload Shear Bolts in

Mainte

nance Instructions

if blades are out of time.

Also, make sure the blade retain ing nuts

are torqued to 60 lb·ft (81 N·m).

Summary of Contents for B18

Page 73: ...69 Operator s Notes...

Page 74: ...70 Operator s Notes...