52

Maintenance Instructions

CHECKING/SERVICING

Tire Pressure

Inflate tires to pressures shown below:

Deck Caster Wheel = 20 PSI (137 kPa)

Drive

= 15 PSI (103 kPa)

Tailwheel

= 20 PSI (137 kPa)

Wheel Nut Torque

Check the eight (8) Drive Tire mounting nuts.

Every

100 hours

they should each be torqued to

75 to 85 lb

·

ft (102 to 115 N

·

m).

Sharpen Mower Blades

Check mower blade(s) for

straightness, sharp-

ness, condition of

the cutting edge,

and

balance

every 10 hours

of operation (or more often when

mowing abrasive type grass or operating on sandy

soils).

Replace blades if worn, bent, cracked, or

otherwise damaged

(refer to

REPLACING/RE-

PAIRING

the

Mower Blades

in this section). Use

the following procedure to check and sharpen

blades:

NOTE: Keep blades sharp

- cutting with dull

blades not only yields a poor mowing job but slows

the cutting speed of the mower and causes extra

wear on the engine and blade drive by pulling hard.

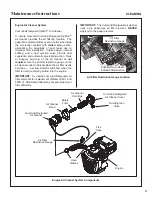

1. Stop the engine, remove ignition key, and dis-

connect the spark plug wires

before

raising the

mower deck to service blades.

2. Raise the deck and

secure

it in the

TILT-UP

po sition (refer to

Deck Secured in TILT-UP Po-

sition

photo in

CLEANING

of

Grass Buildup

in Mower Deck Housing

in this section).

DANGER

NEVER operate cutter blades with the

deck in the raised position.

NOTE:

PTO shaft must be

disconnected

be-

fore checking blades for straightness.

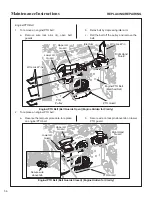

3. Check the blades for

straightness

by marking

the blade tip position inside the deck housing,

and then rotating the opposite end of the blade

to the same position and comparing. If the dif-

ference in blade tip track is

more than 1/8 in.

(3 mm),

the blade is bent and

should be re-

placed.

WARNING

DO NOT try to straighten a blade that is

bent. NEVER weld a broken or cracked

blade. ALWAYS replace with a new blade

to assure safety.

4. If the blade cutting edge is

dull or nicked,

it

should be sharpened. Remove blades for

sharpening by grasping the end of the blade us-

ing a rag or a thick, padded glove, while loosen-

ing and removing the nut, lock washer, and flat

washer that mounts the blade.

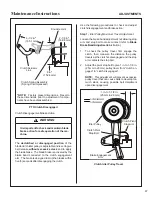

5. Grind cutting edge at the same bevel as the

original. Sharpen only the top of the cutting

edge to maintain sharpness.

NOTE:

Blades can be sharpened with an elec-

tric blade sharpener, conventional electric grind-

er, or a hand file.

CAUTION

ALWAYS wear eye protection and gloves

when sharpening a blade.

Wing

Tip

Do Not Grind or

Sharpen on Underside

Intersection

Wear Area

Sharpen at

Original 30° Angle

30°

Mower Blade Profile for Sharpening

6. Check blade balance by positioning the blade

horizontally

on a blade balancer or use a nail

or shaft through the center hole. If either end of

the blade rotates downward, grind (remove)

metal on that end until the blade will balance.

The blade is properly balanced when neither

end drops. Balance of a blade is generally

maintained by removing an equal amount of

material from each end of the blade when

sharpening.

Summary of Contents for B18

Page 73: ...69 Operator s Notes...

Page 74: ...70 Operator s Notes...