61

Maintenance Instructions

CHECKING/SERVICING

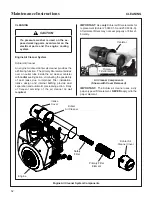

Engine Starter

Yearly or every 500 hours

disassemble and clean

the solenoid shift starter. Refer to the Kohler Service

Manual for this procedure or contact an authorized

Kohler engine dealer to perform this service.

Blade Brake Action

WARNING

It is important to check and maintain

blade brake action for safe operation of

the ma chine.

Check the function of the cutter blade brake by

engaging the blade clutch (PTO), operating the

engine at full throttle, then disengaging the clutch

and measuring how quickly the blades stop. Watch

the rotation of the blade drive shaft as a visual indi

cation that movement has stopped. If the brake is

working properly, all rotation will stop five (5)

seconds after disengagement

of the clutch. If the

brake system malfunctions blades do not stop in

five (5) seconds adjust or repair the brake before

operating the mower. Refer to

ADJUSTMENTS

for

Clutch Disengagement/Brake Action,

Step 2 -

Blade

Brake Band Adjustment,

on page 76.

Safety Switch System

WARNING

It is important to check and maintain the

safety switch system for safe operation of

the machine.

There are three (3) safety interlock switches on the

tractor; Seat Switch, FSC NeutralPark Switch, and

PTO Switch.

NOTE:

There is a 1/2 second time delay function on

the seat switch to avoid engine power interruption

when driving over bumps.

If any of the following conditions occur during start

ing or operating, a safety interlock switch may be

malfunctioning. Contact your Walker dealer for trou

bleshooting and/or replacement.

● With or without an operator in the seat, the en

gine starts with the Forward Speed Control (FSC)

and/or the PTO engaged.

● With an operator in the seat, the engine starts

but dies soon after the Forward Speed Control

(FSC) or PTO is engaged.

●

Without

an operator on the seat, the engine

continues to run with the Forward Speed Control

(FSC) and/or PTO engaged.

● With an operator in the seat, the Forward Speed

Control (FSC) and PTO disengaged and warning

horn sounding, but the starter will not engage.

Forward Speed Control Friction Lock

The FSC friction lock is designed to

hold the se-

lected forward travel speed

when the steering le

vers are moved and yet the friction is not too heavy

to make

moving the FSC control

difficult (too much

friction). The procedure for checking the FSC fric

tion lock is as follows:

1. With the engine off, place the FSC in the full

FORWARD

position and pull both steering le

vers back; the FSC lever should not move. If

the FSC lever moves back when the steering

levers are pulled back, the

friction needs to be

increased.

2. With the steering levers held back, move the

FSC lever back from the

FORWARD

position.

With a proper amount of friction adjusted, the

FSC lever should move back with a slight

amount of resistance (friction). If the FSC lever

movement is “stiff”,

the friction needs to be

decreased.

If the FSC friction lock needs to be adjusted, refer to

ADJUSTMENTS

for

Step 7 - Forward Speed Con-

trol Friction Adjustment

in this section.