71

Maintenance Instructions

ADJUSTMENTS

WARNING

The following adjustments are made with

the engine running. Keep all body parts

and tools away from rotating and hot com-

ponents, and secure all loose clothing.

4. With the body lowered and the FSC in

NEU-

TRAL-PARK,

start the engine. With the engine

at normal operating speed, check for movement

of the drive wheels.

5. Lift the body to access the steering adjustment

components.

NOTE:

It may be necessary to tighten the FSC

friction adjustment if the transmissions are

moved out of neutral when the body is raised.

Refer to

Step 7 -

Forward Speed Control Friction

Adjustment

later in this section for location of the

FSC friction adjustment nut.

6. Using a wrench on one tracking adjustment nut,

rotate the control rod

clockwise

just until the

wheel on that side begins

to move

forward.

Then, counting the turns required, rotate the

control rod

counterclockwise

just until the

wheel stops and then begins

to move in re-

verse.

Rotate the control rod back clockwise

half the number of turns required to make the

wheel go from moving forward to reverse. The

transmission is now centered in the neutral win

dow. Tighten the jam nut on the ball joint and

repeat the same procedure on the other trans

mission.

7. Turn off the engine, and then lower the drive

tires onto the ground.

Step 4 - Full Forward Speed Adjustment

1. Move the FSC to the full

FORWARD

speed po

sition.

2. Raise the body. The set screws in the left and

right Transmission Control Arms should not be

contacting the locating stud in the transaxle. If

they are, back the set screws out until they do

not touch.

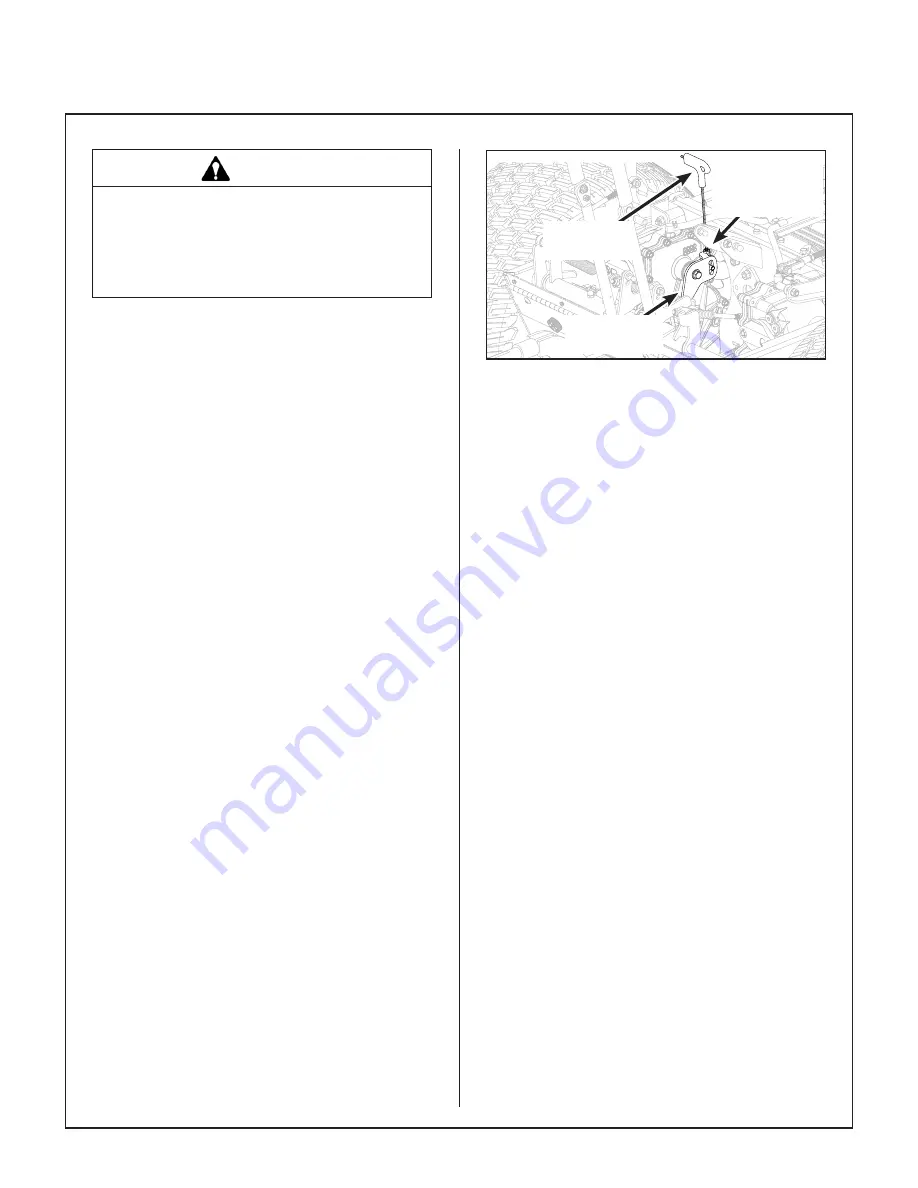

THandle

Hex Wrench

Maximum

Speed Tracking

Adjustment

Transmission

Control Arm

Maximum Speed Tracking Adjustment

(Shown with Parts Removed for Clarity)

Step 5 - Straight Tracking Adjustment

1. Sit in the seat, start the engine, set throttle at full

speed, and with the FSC in the

NEUTRAL-

PARK

position check for movement of either

drive wheel (if either wheel moves backward or

for ward, refer to

Step 3 -

Neutral Function Ad-

justment

and readjust).

2. Check for straight ground tracking on a level

surface (with hands off the steering levers). Set

the FSC at several different speeds and ob

serve if the machine moves in a straight line

(use cement joint or other line on ground for

reference).

3. If travel is not straight, shorten the control rod

on the slow side by turning the tracking adjust

ment nut clockwise. If straight tracking and

neutral can not be achieved, turn the tracking

adjustment nut counterclockwise until neutral is

restored.

4. Lengthen the control rod of the faster side by

turning the tracking adjustment nut counter

clockwise to match the slower side while main

taining the neutral position.

IMPORTANT:

After tracking adjustments are

complete, confirm that there is at least one (1)

thread visible on both control rods past the

tracking adjustment nuts.