FoldSmart™ Installation and Maintenance Manual

Revision 1 - MAY 2023

109

INSTALLING VEHICLE DETECTORS AND LOOPS

Installing Vehicle Detectors and Loops

A vehicle detector passes a small current flow through the “loop” which then becomes an inductive

coil. When a vehicle passes over the loop, the detector senses the resultant drop in the inductance, and

actuates the detector output.

Loop Configurations:

Configurations differ depending on the application.

Rules to Follow for Security Gate Applications:

The side of the loop closest to the gate must be located at least 4 ft (122cm) from the line of travel.

1�

The shortest side of the loop should be between 6 and 8 feet (1.8 x 2.4m) in length. The longest side

of the loop should be between 6 and 20 feet (1.8 x 6.1m) in length. For applications that need to

span a wide area, use several smaller loops. Do not connect more than 200 square feet (18.6 sq. m)

of loop area to a single detector.

2�

In applications with multiple loops, keep each loop at least 6 feet (1.8m) apart. This avoids “cross

talk”. It is possible to have loops closer together by selecting different frequencies. An advantage

of using model HY5B detectors is that problematic “cross talk” is not possible.

3. For greater sensitivity and less chance of false calls caused by the motion of the gate, it is better to

use multiple smaller loops, connected in a series circuit, to one detector instead of a single large

loop.

4�

To avoid interference, keep loops at least 2 inches (5cm) above any reinforcing steel. Do not route

loop wires with, or in close proximity to, any other conductors, including other loop leads, unless

shielded lead-in cable is used. Never route high voltage circuits in PVC conduit near a loop.

5�

Loop and lead-in wire should be one continuous piece. Avoid splices, if possible. If a splice is

necessary for any reason, “pot” the splice in epoxy or use heat shrink to ensure that the quality of

the splice covering is the same as the original wire jacket.

6�

Use only 14-, 16-, or 18-gauge stranded wire with a direct burial jacket. Cross

-

linked polyethylene

insulation types, such as XLPE or XHHW, will last much longer and are less prone to damage during

installation than conventional insulation types. Preformed loops can be used before road surfacing

or under pavers.

7�

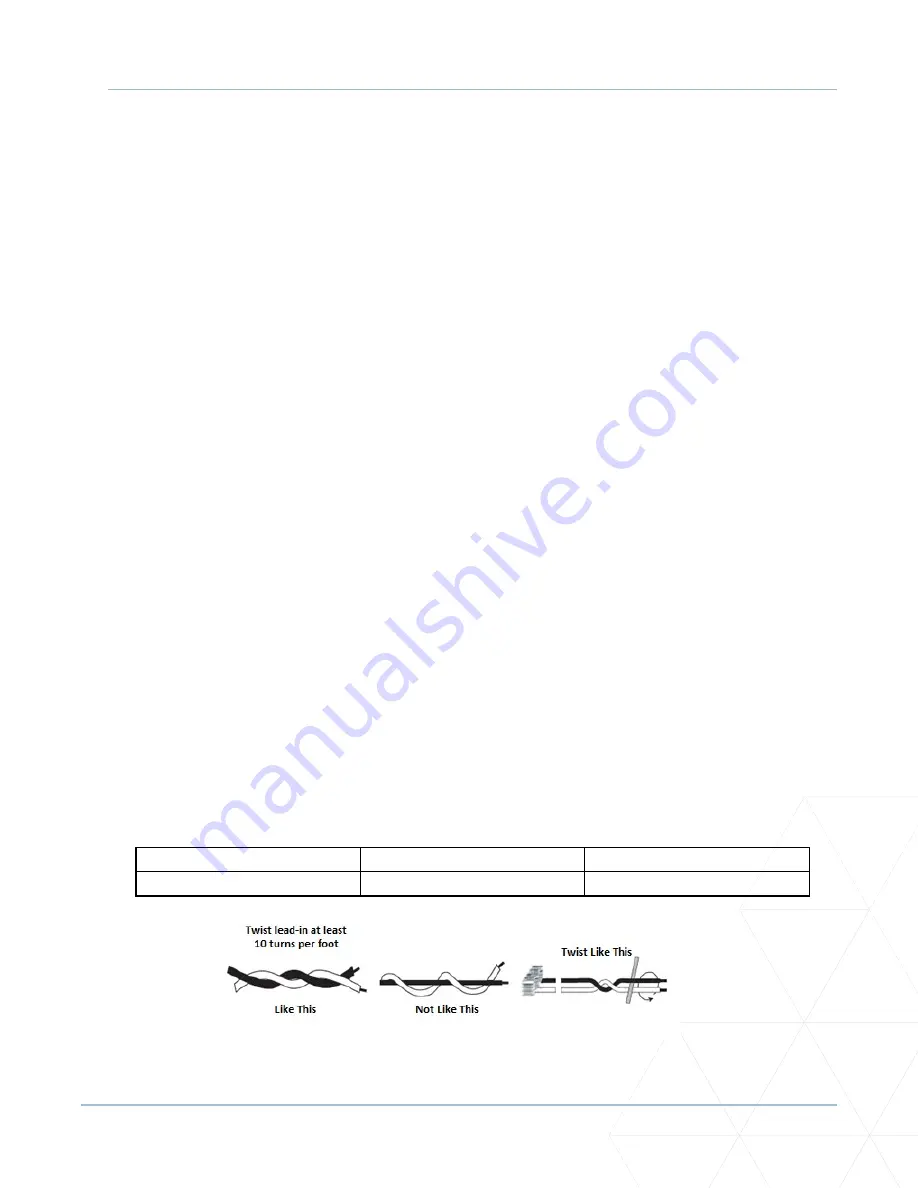

Twist loose tails of lead-in wires tightly, approximately ten times per foot. See Figure 22.

8�

Follow this guide for the correct number of turns in the loop;

12 to 20 sq. ft. = 5 turns

20 to 60 sq. ft. = 4 turns

60 to 240 sq. ft. = 3 turns

3.7 to 6.1 sq. m = 5 turns

6.1 to 18.3 sq. m = 4 turns

18.3 to 73.1 sq. m = 3 turns

Figure 22

.

Lead-in Wire Twisting

Summary of Contents for FOLDSMART

Page 36: ...36 wallaceperimetersecurity com Phone 866 300 1110 FOLDSMART GATE INSTALLATION ...

Page 38: ...38 wallaceperimetersecurity com Phone 866 300 1110 FOLDSMART GATE INSTALLATION ...

Page 146: ......

Page 147: ...FoldSmart XT Drawings Generic Site Layout and Options ...

Page 148: ......

Page 149: ......

Page 150: ......

Page 151: ......

Page 152: ......

Page 153: ......

Page 154: ......

Page 155: ......

Page 156: ......

Page 157: ......

Page 158: ......

Page 160: ......