Technical Manual

121410-0

FluidWorker Mobility Kit

SAFETY

Risk of personal injury

•

Never use on sloped ground.

•

Never use on uneven ground.

•

Always activate brakes when stationary.

Risk of contamination

•

When not in operation, never leave the Fluidworker more than 24h without thourough

draining and cleaning. Use a wet vacuum for draining and system cleaner for disinfection. If liquid

remains in the FluidWorker, there is a risk that bacteria will grow to high levels. This can

contaminate when the product is put into service.

MOVING THE FLUIDWORKER BETWEEN TANKS

Note:

FluidWorker reduces bacteria in the machine tank it is installed on. Before moving to the next

machine, the root cause of bacterial problems must be resolved and the fluid must be adjusted to

the concentration and pH value recommended by the process fluid supplier.

1.

Drain the FluidWorker: With the FluidWorker in operation, demount the tank bracket and carefully

lift the pipes above water level. Wait until no more fluid ejects.

2.

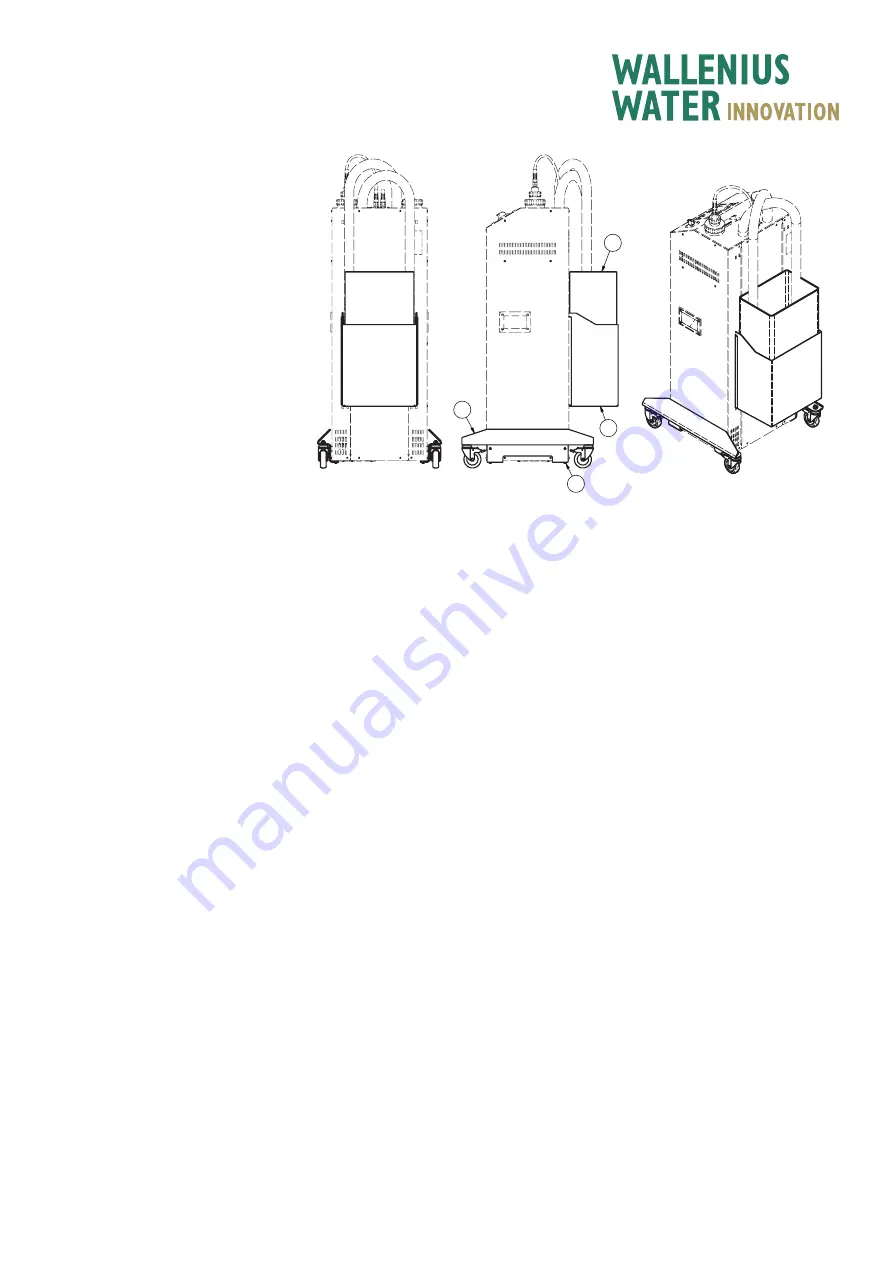

Place the pipes and tank bracket into the container (4) on the back of the FluidWorker.

3.

Turn the FluidWorker off, swith the main switch off and unplug the powerplug.

4.

For thorough draining (recommended), open the priming tank and suck dry using a wet vacuum.

5.

Move to the new tank.

6.

Carefully mount inlet and outlet pipes, making sure inlet is midway between surface and

bottom and outlet is directed to create optimal circulation in the tank.

7.

Fill up the priming tank with water or process fluid. Close the lid. Turn the FluidWorker on.

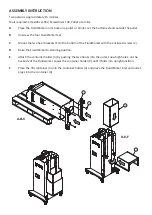

CONTENT

1: Wheel bracket

2x

2: Screw MRT FZB M6x20

4x

3: Container holder

1x

4: Container 30L

1x

2

1

3

4