Safety

BX36S

3PH Self-feed Chipper

12

6.9 Safety Training

1.

Safety is a primary concern in the design and

manufacture of our products. Unfortunately, our

efforts to provide safe equipment can be wiped

out by a single careless act of an operator or

bystander.

2.

In addition to the design and configuration of

equipment, hazard control and accident prevention

are dependent upon the awareness, concern,

prudence and proper training of personnel involved

in the operation, transport, maintenance and

storage of this equipment.

3.

The best safety feature is an

informed, careful operator—we

ask you to be that kind of an

operator. It is the operator's

responsibility to read, understand

and follow ALL safety and

operation instructions in the

manual. Accidents can be

avoided.

4.

Working with unfamiliar equipment can lead

to careless injuries. Read this manual before

assembly or using the machine to acquaint

yourself with it. If this machine is used by any

person other than yourself, or is loaned or rented,

it is the machine owner's responsibility to make

certain that prior to using, the operator:

- reads and understands the owner's manual

- is instructed in safe and proper use of the

equipment

- understands and knows how to perform the

Safe Condition procedure

5.

Train all new personnel and review instructions

frequently with existing workers. Be certain only

a properly trained and physically able person will

use the machinery. A person who has not read and

understood all use and safety instructions is not

qualified to use the machine. An untrained operator

exposes himself and bystanders to possible

serious injury or death. If the elderly are assisting

with the work, their physical limitations need to be

recognized and accommodated.

6.

Know your controls and how to stop the machine

and the tractor quickly in an emergency. Read this

manual thoroughly..

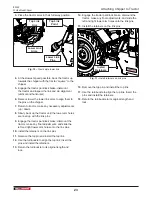

6.10 Maintenance Safety

Place the machine in a Safe Condition before

performing any service, maintenance work or storage

preparation. See

Good maintenance is your responsibility. Poor

maintenance is an invitation to trouble.

Follow good shop practices.

•

Keep service area clean and

dry.

•

Be sure electrical outlets and

tools are properly grounded.

•

Use adequate light for the

job at hand.

•

Make sure there is plenty of ventilation. Never

operate the engine of the towing vehicle in a

closed building. The exhaust fumes may cause

asphyxiation.

•

Before working on this machine, set the brake and

turn the engine off.

•

Never work under equipment unless it is blocked

securely.

•

Always use personal protection devices such as

eye, hand and hearing protectors, when performing

any service or maintenance work. Use heavy or

leather gloves when handling blades.

•

Where replacement parts are necessary for

periodic maintenance and servicing, genuine

factory replacement parts must be used to restore

your equipment to original specifications. The

manufacturer will not be responsible for injuries or

damages caused by use of unapproved parts and/

or accessories.

•

A

fire extinguisher and first aid kit should be kept

readily accessible while performing maintenance

on this equipment.

•

Periodically tighten all bolts, nuts and screws and

check that all electrical and fuel connections are

properly secured.

•

When completing a maintenance or service

function, make sure all safety shields and devices

are installed before placing unit in service.

Summary of Contents for BX36S

Page 1: ...OPERATOR S MANUAL 3PHSelf feedChipper BX36S BX52S BX72S BX102S...

Page 51: ......

Page 52: ...www wallensteinequipment com...