Attaching Chipper to Tractor

BX36S

3PH Self-feed Chipper

22

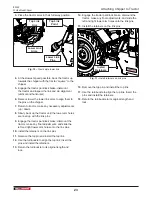

9.

Use a file to remove the burrs from the edges that

were cut.

10.

Assemble the two ends of the shaft.

11.

Make sure the shaft can telescope freely. If it does

not, separate the two parts and inspect for burrs or

cuttings on the shaft ends. Be sure it telescopes

freely before installing.

12.

Raise and lower the chipper. A correctly sized shaft

should not bottom out or come apart.

NOTE: Telescoping PTO shaft should overlap at

least 6 in (150 mm) under load.

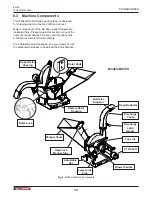

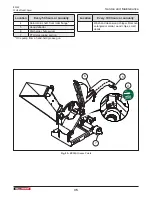

10. Attaching Chipper to

Tractor

The BX36S, BX52S and BX72S are Category One,

3-point hitch, and are quick hitch and iMatch™

compatible.

BX102S is Category Two, 3-point hitch only, and is also

quick hitch and iMatch™ compatible.

For maximum life and safety, connect PTO shaft with

machine as level as possible when the chipper is in the

lowered (working) position.

NOTE: Be sure the telescoping portion of the

shaft is greased and free of dirt.

NOTE: The lower ski is adjustable. Ski

adjustment may be required to help make

the PTO connection as level as possible.

See Machine Set-up on page 26.

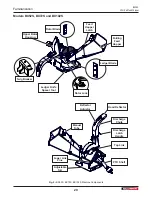

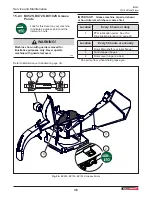

The BX Series chippers feature clevis style (3-position)

lower link attachment points. To use the center

attachment point, a 7/8 in diameter pin is required (not

supplied). Use the existing bolt in implement pin for the

inside or outside points.

10.1 Procedure

1.

Clear the area of bystanders, especially small

children.

2.

Make sure there is enough room and clearance to

safely reverse the tractor to the chipper.

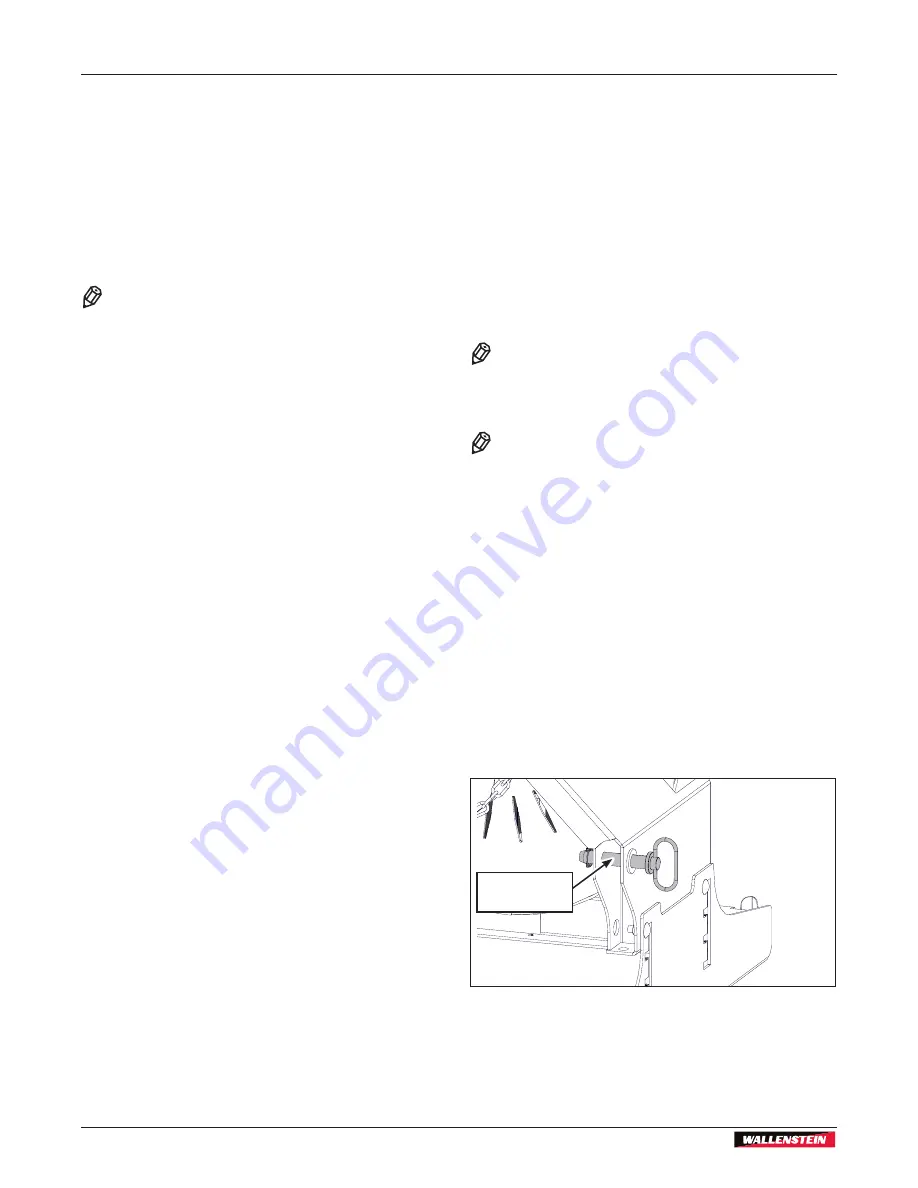

Lower Link

Fig. 9 –

Clevis style lower link

Summary of Contents for BX36S

Page 1: ...OPERATOR S MANUAL 3PHSelf feedChipper BX36S BX52S BX72S BX102S...

Page 51: ......

Page 52: ...www wallensteinequipment com...