BXM32, BXM42

3-point Hitch Chipper-Shredder

Service and Maintenance

41

Replace broken shear pins with one the same size. Always

determine the cause of the problem and correct it before

resuming work. Shear pins are available from your distributor or

dealer.

9.5

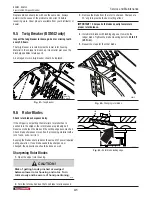

Twig Breaker (BXM42 only)

Inspect the twig breaker for damage, bent or missing teeth

every 50 hours.

The twig breaker is located inside the lower rotor housing.

Material in the chipper is broken up into smaller pieces as the

discharge paddles rotate past it.

A damaged or worn twig breaker should be replaced.

00914

Fig. 41 –

Twig Breaker

9.6 Rotor Blades

Check rotor blade sharpness daily.

If the chipper is not pulling the material or material has to

pushed into the chipper, the rotor blades are probably dull.

Reverse or sharpen the blades if the cutting edge becomes dull.

Check blade sharpness more often if processing material with a

lot of sand, soil or dirt in it.

Keeping the blades sharp reduces the amount of power required

during operation. If one blade needs to be sharpened or

changed, the opposite one should be done as well.

Sharpening Rotor Blades

1.

Open the upper rotor housing.

CAUTION!

Risk of getting hands pinched or wedged

between lower rotor housing and rotor. Turn

rotor slowly and be aware of hand positioning.

W032

2.

Turn the rotor by hand so that one blade is fully exposed.

3.

Remove the blade from the rotor to sharpen. Sharpen at a

45° angle to provide the best cutting effect.

IMPORTANT! Sharpen both blades equally to maintain

proper rotor balance.

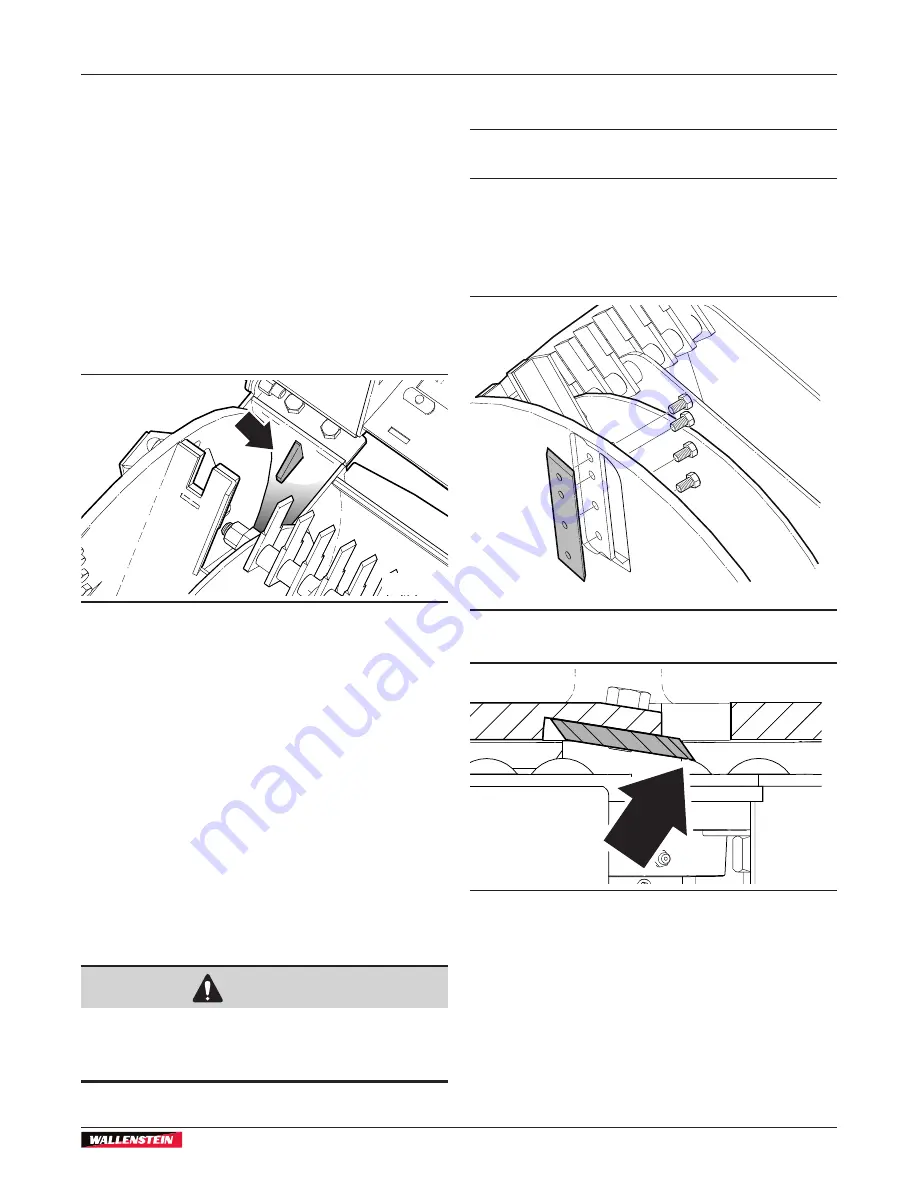

4.

Install rotor blades with leading edge out, towards the

ledger blade. Tighten the blade mounting bolts to

33 lbf•ft

(45 N•m)

.

5.

Repeat the steps for the other blade.

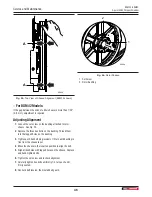

00915

Fig. 42 –

Changing rotor blade

00872

Fig. 43 –

Rotor blade leading edge