Service and Maintenance

BXM32, BXM42

3-point Hitch Chipper-Shredder

42

9.7

Ledger Knife

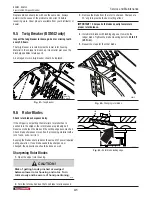

Observe ledger knife performance daily. Check the ledger

knife sharpness every 50 hours.

The ledger knife is bolted in the lower rotor housing assembly.

As the rotor turns, material fed into the chipper is sheared off at

the ledger knife by the rotor blades.

When the corner of the ledger knife facing the rotor blade rounds

over, the blade can be removed and re-installed with a different

corner facing the rotor blade. Once all four corners have been

rounded, remove the knife to sharpen or replace it.

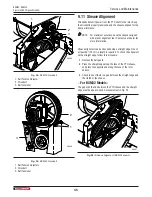

00916

Fig. 44 –

Ledger knife on lower rotor housing

To obtain the best chipper performance, check the clearance

between the rotor blade and stationary ledger blade every 50

hours.

9.7.1

Ledger Knife Clearance

Use the ledger setting gauge to check knife clearance

. The

thickness of the gauge is the correct ledger blade clearance.

If spacing is in excess of the gauge thickness, adjust the

clearance.

Checking

1.

Open the upper rotor housing.

CAUTION!

Risk of getting hands pinched or wedged

between lower rotor housing and rotor. Turn

rotor slowly and be aware of hand positioning.

W032

2.

Turn the rotor by hand so that one rotor blade edge is next

to the ledger knife.

3.

Slide the end of the ledger gauge down between the rotor

blade and the ledger knife.

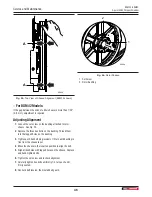

00917

Fig. 45 –

Inserting Gauge

4.

Turn the rotor past the ledger knife with the gauge inserted

between them to check clearance. The gauge should be

tight. Check both knives.

1

3

2

00877

Fig. 46 –

Checking ledger knife clearance

1. Rotor Blades

2. Gauge

3. Ledger Knife