44

Obstructed discharge.

Clear debris from discharge chute.

Ensure machine is off

Rotor plugged.

Inspect and clear chipper hopper

lower rotor housing and rotor.

Ensure machine is off

Loose belt.

Follow tension adjustment

procedure and tighten belt.

Ensure machine is off

Shear pin failure

Replace shearpin

Ensure machine is off

Broken belt.

Follow belt replacement procedure

and replace belt.

Ensure machine is off

Low engine speed.

Check that throttle is set to

maximum.

Blades and/or knives

are dull.

Rotate, sharpen or replace blade

and/or knives.

Ensure machine is off

Rotor blade angle

wrong, improper

angle.

Re-sharpen knives to specified

angle and check that blade is

installed properly.

Ensure machine is off

Obstructed discharge.

Clear debris from discharge chute.

Ensure machine is off

Broken or missing

blade or knife.

Replace broken/missing blade or

knife.

Ensure machine is off.

Rotor may be bent

Check rotor to see if it wobbles.

Replace rotor

Ensure machine is off, call

technician for repair

ChopBlock or Twig

Breaker may be

damaged

Inspect ChopBlock and Twig

Breaker, replace if damaged.

Ensure machine is off.

Broken or missing

blade or knife.

Replace broken/missing blade or

knife.

Ensure machine is off.

Knives in shredder

improperly re-

installed

Check installation of knives and

adjust as required, per maintenance

instructions.

Ensure machine is off.

Obstructed discharge.

Clear debris from discharge chute

Ensure machine is off

Engaging PTO too

quickly

Engage PTO slowly at low RPM, then

increase speed. Ensure hoppers and

rotor housing are empty.

Feeding in too much

material

Feed smaller amounts into shredder

hopper.

Feeding material too

quickly

Feed larger material slowly into

chipper hopper.

Rotor plugged.

Inspect and clear chipper hopper

lower rotor housing and rotor.

Ensure machine is off

Green material will

not discharge.

Allow material to dry or alternate

dry/wet material.

Chipper blade

clearance too large.

Set clearance to 1/32 to 1/16 " (.76 -

1.52 mm). Use chipper clearance

tool (see accessories)

Ensure machine is off.

Dull blades and/or

knives.

Rotate, sharpen or replace blade

and/or knives

Ensure machine is off.

Unusual vibration while

running.

Mulch too Course

Machine requires excessive

power or stalls.

PROBLEM

CAUSE

SOLUTION

CAUTION

Rotor does not turn

Slow feeding.

Obstructed discharge.

Clear debris from discharge chute.

Ensure machine is off

Rotor plugged.

Inspect and clear chipper hopper

lower rotor housing and rotor.

Ensure machine is off

Loose belt.

Follow tension adjustment

procedure and tighten belt.

Ensure machine is off

Shear pin failure

Replace shearpin

Ensure machine is off

Broken belt.

Follow belt replacement procedure

and replace belt.

Ensure machine is off

Low engine speed.

Check that throttle is set to

maximum.

Blades and/or knives

are dull.

Rotate, sharpen or replace blade

and/or knives.

Ensure machine is off

Rotor blade angle

wrong, improper

angle.

Re-sharpen knives to specified

angle and check that blade is

installed properly.

Ensure machine is off

Obstructed discharge.

Clear debris from discharge chute.

Ensure machine is off

Broken or missing

blade or knife.

Replace broken/missing blade or

knife.

Ensure machine is off.

Rotor may be bent

Check rotor to see if it wobbles.

Replace rotor

Ensure machine is off, call

technician for repair

ChopBlock or Twig

Breaker may be

damaged

Inspect ChopBlock and Twig

Breaker, replace if damaged.

Ensure machine is off.

Broken or missing

blade or knife.

Replace broken/missing blade or

knife.

Ensure machine is off.

Knives in shredder

improperly re-

installed

Check installation of knives and

adjust as required, per maintenance

instructions.

Ensure machine is off.

Obstructed discharge.

Clear debris from discharge chute

Ensure machine is off

Engaging PTO too

quickly

Engage PTO slowly at low RPM, then

increase speed. Ensure hoppers and

rotor housing are empty.

Feeding in too much

material

Feed smaller amounts into shredder

hopper.

Feeding material too

quickly

Feed larger material slowly into

chipper hopper.

Rotor plugged.

Inspect and clear chipper hopper

lower rotor housing and rotor.

Ensure machine is off

Green material will

not discharge.

Allow material to dry or alternate

dry/wet material.

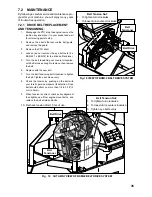

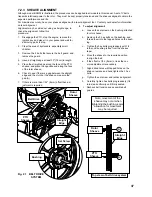

Chipper blade

clearance too large.

Set clearance to 1/32 to 1/16 " (.76 -

1.52 mm). Use chipper clearance

tool (see accessories)

Ensure machine is off.

Dull blades and/or

knives.

Rotate, sharpen or replace blade

and/or knives

Ensure machine is off.

Unusual vibration while

running.

Mulch too Course

Machine requires excessive

power or stalls.

PROBLEM

CAUSE

SOLUTION

CAUTION

Rotor does not turn

Slow feeding.

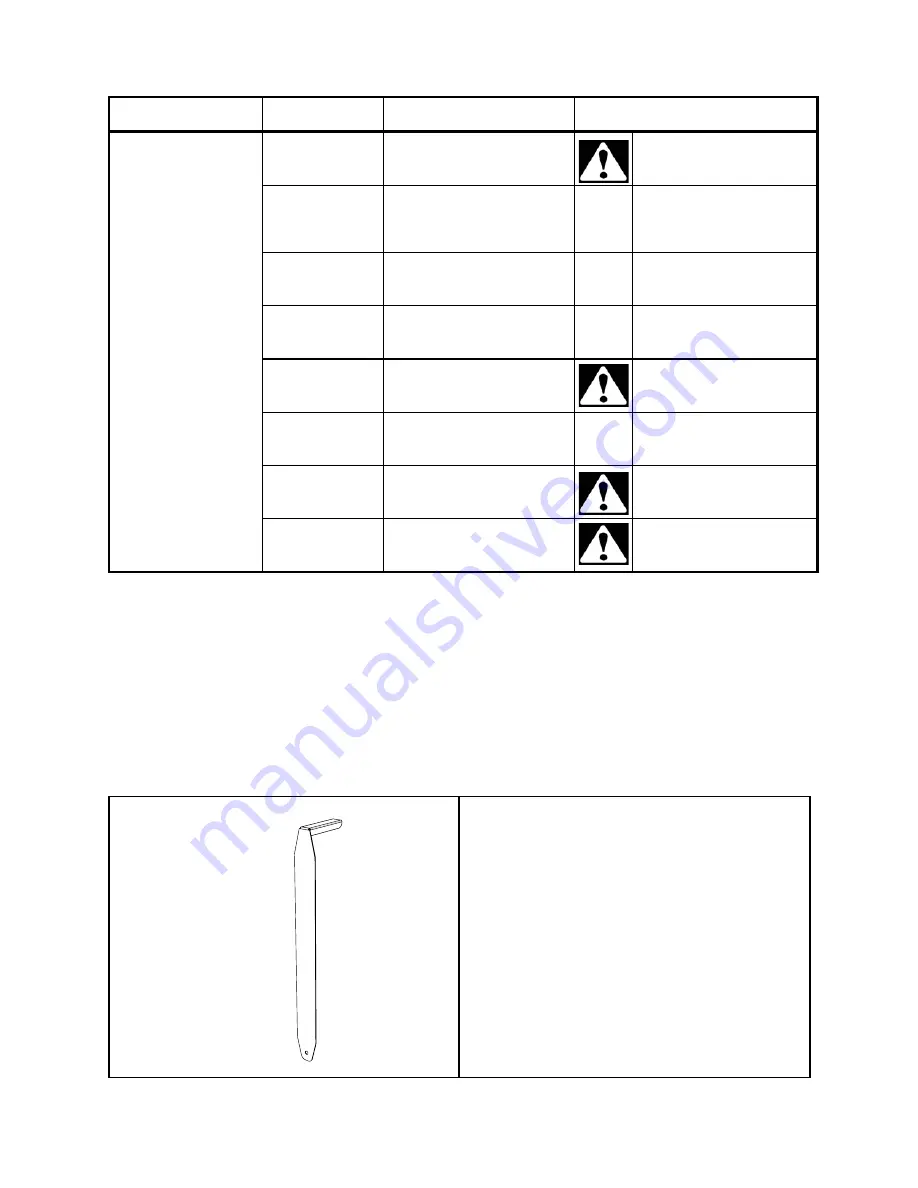

9 ACCESSORIES

Call your dealer for pricing and availability

For replacement parts, go to

www.embmfg.com

and click on "Parts and Manuals" to download the latest

parts manual for you model splitter, then call your dealer to order.

For

BXM Series Chipper / Shredders

An easy and accurate way of setting the critical

clearances between the ledger blade and the rotor

chipper blade.

#1012L269 LEDGER CLEARANCE

SETTING GAUGE

#1012L269

TROUBLE SHOOTING CONTINUED

Summary of Contents for BXM32

Page 48: ...PRINTED IN CANADA ...