19

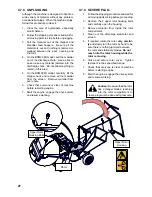

4�3 MACHINE BREAK-IN

Although there are no operational restrictions on the

Chipper-Shredder when used for the first time, it is

recommended that the following mechanical items

be checked:

A.

After operating for 1 hour:

1. Torque all fasteners and hardware.

2. Check condition of rotor bearings.

3. Check the condition and clearance of the

knives, chop-block and stationary blades.

Adjust or replace as required.

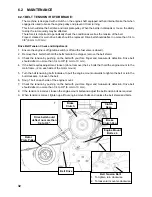

4. Check belt drive system: Tension and

pulley alignment.

5. Check the condition of the hopper gate

in the shredder feed hopper. The hopper

gate must move freely back into position

to ensure the safety of the operator by

preventing wood from flying out.

6. Check for entangled material. Remove all

entangled material before resuming work.

7. Check engine fluid levels. Top up as

required.

8. Lubricate all grease fittings.

B.

After operating for 10 hours:

1. Repeat steps 1 through 8 listed above.

(Section A)

2. Change engine oil.

3. Go to the normal servicing and maintenance

schedule as defined in the Maintenance

Section.

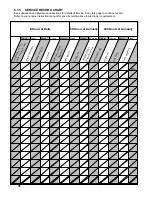

4�4 PRE-OPERATION CHECKLIST

Efficient and safe operation of the Wallenstein

Chipper-Shredder requires that each operator

reads and understands the using procedures

and all related safety precautions outlined in this

section. A preoperational checklist is provided for

the operator. It is important for both the personal

safety and maintaining good mechanical condition

that this checklist is followed.

Before operating the Chipper-Shredder and each

time thereafter, the following areas should be

checked off:

Pre-Operation Checklist

P

Check and lubricate the machine per the schedule

outline in the Maintenance Section.

Check the rotor housing and discharge chute,.

Remove any blockages, twine, wire or other

material that has become entangled .

Check the condition and clearance of the twig-

breaker, rotor and stationary blades. Adjust or

replace as required.

Check that all bearings turn freely. Replace any

that are rough or seized.

Check and ensure that all covers, guards and

shields are in place, secured and functioning as

designed

Check all fasteners and tighten, and esure your

equipment is working and in good repair.

Check that personal protection equipment

including hard hat, safety glasses, safety shoes,

safety vest, hearing protection and gloves are used

and in good repair.

Check that all loose fitting clothing or jewellery is

not worn and loose long hair is tied back.