30

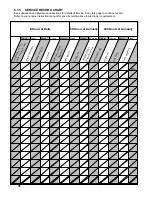

Location

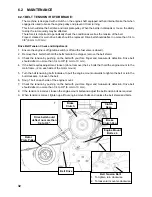

Grease Points - 100 hrs or Annually

1

Rotor Main Shaft Front Flange Bearing

2

Rotor Main Shaft

Rear

Flange Bearing

grease with one shot of grease

Look for this label on your machine, it indicates

a grease point and the number of hours be

-

tween greasing.

100

Z94427

1

100

Z94427

2

100

Z94427

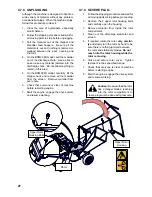

Chop Block: check

every 8 hrs.

Rotor blades: check

daily, test sharpness

every 50 hrs

Ledger blade: check

daily, test sharpness

every 50 hrs

Shredder blades: check

daily, test sharpness

every 50 hrs

Remove the belt shield to

gain access to the grease

zerk

On a regular basis check

all nuts, bolts and screws

and ensure they are all

properly secured

Ensure machine is in safe mode when

performing any maintenance or service.

WARNING

6�1�4 SERVICE ILLUSTRATION

This illustration shows the general location of

service points for all models in this manual.

Refer to your engine instruction manual

for specific maintenance instructions /

requirements

Twig Breaker:

check every 8 hrs.

BXMC34B